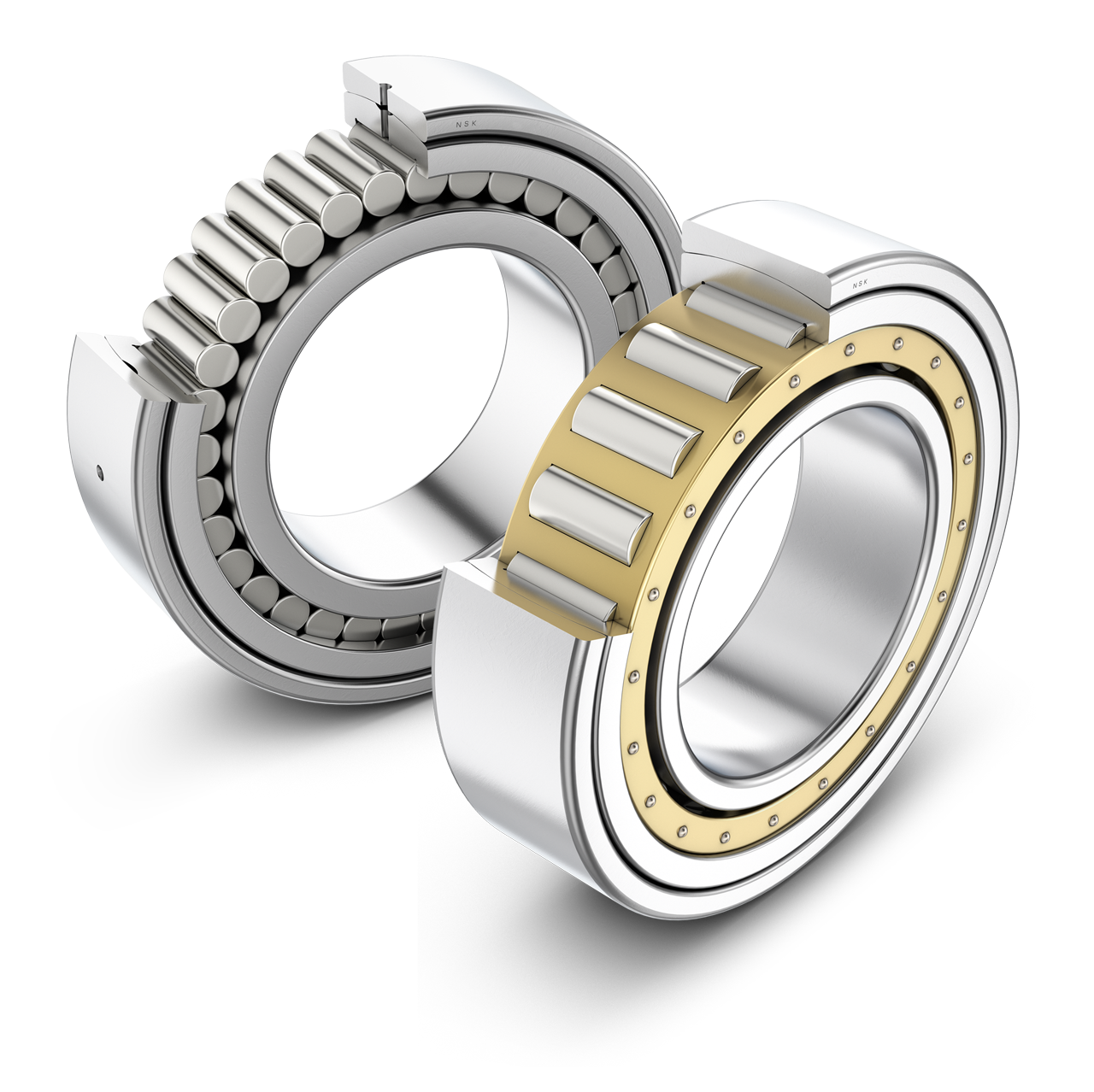

Product Description

PRODUCT PICTURES:

OUR SERVICES

We can provide manufacturing capabilities and services of regular bearings for you, or customized non-standard bearings as you required.

BEARING:

— Dimensions

— Material

— Tolerance standard

APPEARANCE:

— Logo (Laser Marking)

— Package Design

40+ YEARS EXPERIENCE

CONTINUOUS AND STABLE DELIVERY OF PRODUCTS.

With over 40 years experience of the bearing manufacturing, we know how to make good bearings with less cost consistently and efficiently.

We use advanced CNC turning, grinding, and superfinishing machines to ensure high, stable, and accurate machining. All of your goods, from the most economical category, to the highest rated category, will always be manufactured precisely to the standards you require.

OWN HEAT TREATMENT

CONTROALLABLE COST AND QUALITY.

Heat treatment is 1 of the crucial processes to ensure high performance of bearing materials. Compared with other manufacturers, we can produce higher quality bearings at smaller cost, with a more flexible and controllable production schedule, and in a shorter time.

We have 6 heat treatment production lines.

Bearings are heated uniformly, with small deformation and little/no oxidized decarburization, which can make them have high hardness, high fatigue resistance, good wear resistance, dimensional stability, and excellent mechanical strength.

OUTSTXIHU (WEST LAKE) DIS. QUALITY

LOW NOISE, LOW FRICTION AND LONG LIFE.

All our products are characterized by low noise, low friction and long life. This is due to our attention to the roundness, waviness and surface roughness of bearing raceway.

Our products fully meets the requirements of national and international standards according to the testing result of roughness, roundness, hardness, vibration noise, vibration velocity.

PACKING

PACKAGING THAT HELPS SELL.

1, Inner package

Corrosion and Dust Proof PE plastic film / bag packing + Tube packing, or Wrapping tape for larger bearings.

2, Corrugated Individual Box

Our attractive sales-helpful “3-JOYS” package, or as the design of your package.

3, Outer package

Corrugated carton + Wooden pallet

MODERN WELL-ORGANIZED WAREHOUSE

· Constant temperature (20°C) and humidity (RH 52%) warehouse

· Hundreds of models on hand, short delivery time.

HONOR & SYSTEM CERTIFICATES

EXHIBITION

SAMPLES POLICY

FREE SAMPLES AND SHIPPING

We are happy to send you free samples of our bearings for field testing. All transportation costs will be paid by us.

Please note: Depending on the model and value of samples, this policy may not apply!

Please contact our sales staff for details.

TRANSPORTATION

FASTEST DELIVERY TO CUSTOMERS

CUSTOMERS FEEDBACK

PAYMENT TERMS

To facilitate your payment, we offer a variety of options!

FAQ

1, About the lead time.

This depends on several factors, like Is the production schedule tight? Is there a corresponding model in stock, and is there enough of this model in stock? How many pcs of that model would be ordered?

Simply speaking, based on a 20′ GP container load:

| If the model your Preferred is | Sufficient stock | Lead Time |

| Regular models | YES | Within 7 days |

| Regular models | NO | Within 30 days |

| Non-regular model | NO | About 50 days |

For accurate estimate, please contact with our sale stuff. Thanks.

2, Minimum order quantity.

Even just ONE piece of bearing is ok for us.

3, If you don’t know which model is the right choice…

We would like to give you some advise if you like, according to the real situation and demand of your local market. Our purpose is to help you to get proper and right models for your customers, so that you would make a better sales and income finally.

4, Factory Inspection

We surely would welcome you or your representatives to come to our plants or working offices to take a good look and chat with our hardworking CZPT employees. Ask our sales stuff and she/he will arrange that for you. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Bearing Steel |

| Load Direction: | Radial Bearing |

| Separated: | Separated |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do Tapered Roller Bearings Contribute to the Efficiency of Automotive Wheel Hubs?

Tapered roller bearings play a crucial role in enhancing the efficiency and performance of automotive wheel hubs. They are specifically designed to handle both radial and axial loads, making them ideal for supporting the weight of the vehicle, providing smooth rotation, and ensuring safe and reliable operation. Here’s how tapered roller bearings contribute to the efficiency of automotive wheel hubs:

- Load Distribution:

Automotive wheel hubs experience a combination of radial and axial loads due to the vehicle’s weight, acceleration, braking, and cornering forces. Tapered roller bearings efficiently distribute these loads, preventing localized stress concentrations and ensuring uniform load sharing across the bearing components.

- Smooth Rotation:

Tapered roller bearings enable smooth and low-friction rotation of the wheel hub around the axle. This minimizes rolling resistance, leading to improved fuel efficiency and reduced energy consumption.

- Axial Load Handling:

During cornering and steering maneuvers, automotive wheel hubs encounter axial loads. Tapered roller bearings are designed to handle these axial loads without compromising their ability to carry radial loads, ensuring stable and controlled vehicle handling.

- Reduced Friction and Wear:

The tapered geometry and precision design of the rollers and raceways in these bearings minimize friction between components. This results in reduced wear, lower heat generation, and extended bearing life, contributing to long-term efficiency.

- Reliable Performance:

Tapered roller bearings are known for their durability and resistance to wear and fatigue. They maintain their performance even under harsh operating conditions, ensuring consistent and reliable wheel hub operation.

- Enhanced Safety:

The efficiency of tapered roller bearings directly impacts the vehicle’s stability and control. Properly functioning bearings prevent issues like wheel wobbling, uneven tire wear, and compromised steering, contributing to safe driving conditions.

- Easy Replacement:

When maintenance or replacement is required, tapered roller bearings can be easily installed and removed. This simplifies the servicing process and reduces vehicle downtime.

- Reduced Maintenance Costs:

The long service life and reliability of tapered roller bearings minimize the need for frequent maintenance and replacement, reducing overall maintenance costs for the vehicle owner.

- Optimized Performance:

Efficient wheel hubs with properly functioning tapered roller bearings lead to improved vehicle performance, including better acceleration, braking, handling, and overall drivability.

Overall, tapered roller bearings contribute to the efficiency and effectiveness of automotive wheel hubs, enhancing vehicle performance, safety, and longevity.

What are the potential challenges or limitations of using cylindrical roller bearings in specific industries?

While cylindrical roller bearings offer numerous advantages, there are also certain challenges and limitations associated with their use in specific industries. Let’s explore some of these potential challenges:

- High-Speed Applications:

In industries that require high-speed rotating machinery, such as machine tools or centrifugal compressors, the limitations of cylindrical roller bearings become more pronounced. At high speeds, factors like centrifugal forces, increased operating temperatures, and the potential for roller skidding can impact the bearing’s performance. Special design considerations, such as optimized cage designs, precision manufacturing, and proper lubrication, are necessary to overcome these challenges and ensure reliable operation at high speeds.

- High-Temperature Environments:

In industries like steel production, glass manufacturing, or certain types of furnaces, the operating temperatures can exceed the limits of standard cylindrical roller bearings. High temperatures can cause dimensional changes, affect the lubricant properties, and lead to accelerated wear or premature failure of the bearing components. To address this limitation, specialized high-temperature bearings with heat-resistant materials, advanced lubrication systems, and appropriate sealing mechanisms are required.

- Heavy Load and Shock Loads:

Industries involving heavy machinery, such as construction, mining, or material handling, often subject cylindrical roller bearings to extremely heavy loads or sudden shock loads. These conditions can lead to increased stress, fatigue, or even permanent deformation of the bearing components. To overcome these challenges, bearings with higher load-carrying capacities, robust designs, and enhanced fatigue resistance are necessary. Additionally, proper maintenance practices and regular monitoring are crucial to detect any signs of excessive load or potential failure.

- Contamination and Harsh Environments:

In industries characterized by harsh operating environments, such as agriculture, forestry, or automotive manufacturing, cylindrical roller bearings can face challenges related to contamination, moisture, or exposure to abrasive particles. Contaminants can accelerate wear, cause damage to the bearing surfaces, or impair the lubrication effectiveness. Sealing solutions, effective maintenance practices, and the selection of appropriate bearing materials are essential to mitigate these challenges and ensure reliable performance in such environments.

- Space Limitations:

In certain industries like aerospace or robotics, where space is limited and compact designs are required, the size and dimensions of cylindrical roller bearings can pose challenges. Finding suitable bearing sizes that meet the specific space constraints while still fulfilling the load and performance requirements can be a limitation. In such cases, alternative bearing types or customized bearing solutions may be explored to overcome the space limitations.

It’s important to note that while there may be challenges or limitations associated with using cylindrical roller bearings in specific industries, advancements in bearing technology, materials, and design continue to address and overcome many of these limitations. Consulting with bearing manufacturers, considering application-specific requirements, and implementing appropriate maintenance practices can help mitigate these challenges and ensure the successful use of cylindrical roller bearings in a wide range of industries.

What are the key advantages of using cylindrical roller bearings in various applications?

Cylindrical roller bearings offer several key advantages that make them a preferred choice in various applications. Let’s explore the significant benefits of using cylindrical roller bearings:

- High Radial Load Capacity:

Cylindrical roller bearings are specifically designed to handle high radial loads. Their cylindrical roller arrangement and large contact area with the raceways enable them to distribute loads evenly along the rollers’ length. This characteristic allows cylindrical roller bearings to support heavy machinery components and handle substantial radial forces, making them suitable for applications where the primary load is radial in nature.

- Moderate Thrust Load Capacity:

While their primary function is to carry radial loads, cylindrical roller bearings can also accommodate moderate axial loads. The arrangement of the cylindrical rollers and their contact angle with the raceways enables these bearings to handle limited thrust loads. However, it’s important to note that for applications with predominantly axial loads, other types of bearings, such as thrust bearings, may be more suitable.

- High-Speed Capability:

Cylindrical roller bearings can operate at high speeds, depending on their design and internal clearance. Factors such as cage material, roller design, and lubrication play a role in determining the maximum allowable speed. The ability to operate at high speeds makes cylindrical roller bearings suitable for applications that require efficient and reliable rotation, such as electric motors, gearboxes, and machine tool spindles.

- Application Versatility:

Cylindrical roller bearings find wide applications in various machinery and equipment. They are commonly used in rotating machinery, such as electric motors, gearboxes, pumps, and compressors. Cylindrical roller bearings are also utilized in industries such as automotive, aerospace, construction, and mining, where they support heavy loads and provide rotational motion in critical components. The versatility of cylindrical roller bearings makes them a preferred choice across different sectors.

- Alignment and Compensation:

Cylindrical roller bearings have the ability to accommodate slight misalignments between the inner and outer rings. This feature allows for easier installation and helps compensate for mounting errors or shaft deflections during operation. The axial displacement capability of cylindrical roller bearings can also assist in thermal expansion or contraction of the shaft and housing. This ability to handle misalignment and axial displacement contributes to the overall reliability and longevity of machinery.

- Durability and Longevity:

Cylindrical roller bearings are designed to withstand heavy loads, shocks, and vibrations encountered in various applications. They are manufactured with high-quality materials and undergo stringent quality control processes to ensure durability and reliability. Proper lubrication and maintenance further enhance their longevity and performance, making cylindrical roller bearings a dependable choice for demanding industrial environments.

In summary, cylindrical roller bearings offer significant advantages in terms of high radial load capacity, moderate thrust load capacity, high-speed capability, application versatility, alignment and compensation capabilities, and durability. These advantages make cylindrical roller bearings well-suited for a wide range of machinery applications, contributing to efficient operation, reduced downtime, and extended service life.

editor by CX 2024-02-26