Product Description

XSU 0571 18 Cross Cylindrical Roller Bearingsg Introduction:

The inner and outer rings of these 2 types of crossed cylindrical bearings are of integral structure and can be directly mounted on the end face.

XSU 0571 18 Cross Cylindrical Roller Bearings Display:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Large (200-430mm) |

| Material: | Bearing Steel |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Axial Bearing |

| Samples: |

US$ 255/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do Tapered Roller Bearings Contribute to the Operation of Heavy Machinery like Construction Equipment?

Tapered roller bearings play a vital role in ensuring the efficient and reliable operation of heavy machinery, including construction equipment. These bearings are designed to handle heavy loads, shock, and impact forces commonly encountered in construction and industrial applications. Here’s how tapered roller bearings contribute to the operation of heavy machinery like construction equipment:

- Load Handling Capacity:

Construction equipment experiences substantial static and dynamic loads due to the weight of materials, lifting operations, and ground engagement. Tapered roller bearings are engineered to withstand high loads and distribute them evenly across the bearing components.

- Shock and Impact Resistance:

Construction sites are filled with uneven terrain and obstacles, subjecting machinery to sudden shocks and impacts. Tapered roller bearings’ robust design and geometry enable them to absorb and manage these forces, reducing the risk of premature failure.

- Rotational Smoothness:

Heavy machinery requires smooth and precise movement for accurate positioning and operation. Tapered roller bearings facilitate low-friction rotation, reducing resistance and ensuring smooth motion even under heavy loads.

- Axial Load Capability:

Construction equipment often experiences axial loads caused by uneven terrain, steering, or lifting operations. Tapered roller bearings are well-suited to handle both radial and axial loads, ensuring stability and optimal performance.

- Durability in Harsh Environments:

Construction sites expose equipment to dust, debris, moisture, and extreme temperatures. Tapered roller bearings are designed with seals and protective features that keep contaminants out and maintain lubrication integrity, enhancing bearing longevity.

- Long Service Life:

The robust construction and high-quality materials used in tapered roller bearings contribute to their extended service life in demanding environments. This reduces the frequency of maintenance and replacement, minimizing downtime.

- Consistent Performance:

Tapered roller bearings provide consistent and reliable performance over their operational life, ensuring predictable machinery behavior and precise control.

- Enhanced Safety:

Reliable bearing performance is crucial for the safety of operators and bystanders. Properly functioning tapered roller bearings prevent unexpected failures that could lead to accidents or equipment damage.

- Compatibility with Heavy Loads:

Construction machinery often involves complex multi-axis loading scenarios. Tapered roller bearings’ ability to accommodate axial and radial loads makes them suitable for these demanding applications.

- Versatility in Equipment Types:

Tapered roller bearings are used in a wide range of construction equipment, including excavators, bulldozers, loaders, cranes, and more, contributing to the reliable operation of various machinery types.

Overall, tapered roller bearings enhance the performance, durability, and safety of heavy machinery used in construction applications, making them an indispensable component for the industry.

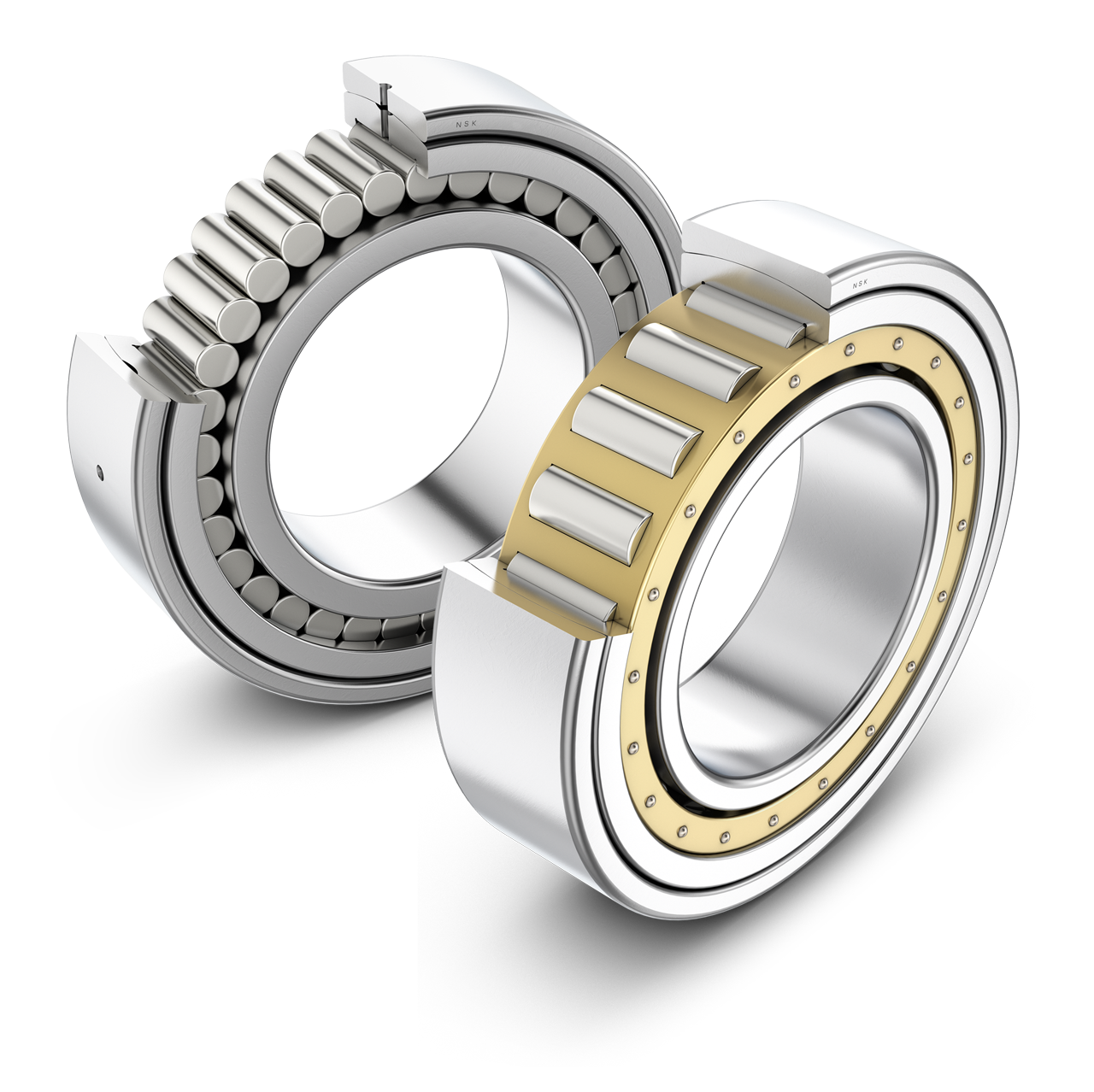

Are there different cage materials commonly used in cylindrical roller bearings?

Yes, there are different cage materials commonly used in cylindrical roller bearings. The cage, also known as a retainer or separator, is a critical component that holds the cylindrical rollers in position and maintains their proper spacing. The choice of cage material depends on various factors such as application requirements, operating conditions, and the desired balance between strength, durability, and cost. Let’s explore some of the commonly used cage materials in cylindrical roller bearings:

- Steel:

Steel cages are widely used in cylindrical roller bearings due to their excellent strength, durability, and wear resistance. Steel cages can withstand high operating temperatures and are suitable for applications with heavy loads and high-speed operation. The steel cages are typically made from low carbon steel, and in some cases, high-strength brass-coated steel or other alloyed steels are used for enhanced performance in demanding environments.

- Brass:

Brass cages offer good strength, high corrosion resistance, and excellent heat dissipation properties. They are commonly used in cylindrical roller bearings for applications that require resistance to harsh operating conditions, such as high temperatures or corrosive environments. Brass cages are particularly suitable for slow to moderate speed applications where their excellent thermal conductivity can help dissipate heat effectively.

- Polyamide (Nylon):

Polyamide cages, often referred to as nylon cages, are lightweight, corrosion-resistant, and have good wear properties. They offer low friction and allow for smooth rolling motion of the cylindrical rollers. Polyamide cages are commonly used in applications where reducing weight and inertia are important considerations, such as automotive and aerospace industries. They are also suitable for applications with moderate speeds and operating temperatures.

- Phenolic Resin:

Phenolic resin cages are known for their high strength, low friction, and excellent dimensional stability. These cages provide good resistance to wear, chemicals, and heat. Phenolic resin cages are commonly used in high-speed cylindrical roller bearings where low cage weight and inertia are crucial for reducing friction and maintaining stable operation at high rotational speeds.

- Other Materials:

In addition to the above-mentioned materials, other cage materials such as aluminum alloys, stainless steel, and engineered plastics may be used in specific applications. Aluminum alloy cages offer lightweight properties and good corrosion resistance, making them suitable for certain industries. Stainless steel cages provide high corrosion resistance and are used when the bearing operates in aggressive environments. Engineered plastics, such as PEEK (polyether ether ketone) or PTFE (polytetrafluoroethylene), are used for their self-lubricating properties, chemical resistance, and low friction characteristics.

The choice of cage material depends on factors such as load, speed, temperature, lubrication, and environmental conditions. Bearing manufacturers carefully select the appropriate cage material to ensure optimal performance, longevity, and reliability of the cylindrical roller bearing in a specific application.

What are the key advantages of using cylindrical roller bearings in various applications?

Cylindrical roller bearings offer several key advantages that make them a preferred choice in various applications. Let’s explore the significant benefits of using cylindrical roller bearings:

- High Radial Load Capacity:

Cylindrical roller bearings are specifically designed to handle high radial loads. Their cylindrical roller arrangement and large contact area with the raceways enable them to distribute loads evenly along the rollers’ length. This characteristic allows cylindrical roller bearings to support heavy machinery components and handle substantial radial forces, making them suitable for applications where the primary load is radial in nature.

- Moderate Thrust Load Capacity:

While their primary function is to carry radial loads, cylindrical roller bearings can also accommodate moderate axial loads. The arrangement of the cylindrical rollers and their contact angle with the raceways enables these bearings to handle limited thrust loads. However, it’s important to note that for applications with predominantly axial loads, other types of bearings, such as thrust bearings, may be more suitable.

- High-Speed Capability:

Cylindrical roller bearings can operate at high speeds, depending on their design and internal clearance. Factors such as cage material, roller design, and lubrication play a role in determining the maximum allowable speed. The ability to operate at high speeds makes cylindrical roller bearings suitable for applications that require efficient and reliable rotation, such as electric motors, gearboxes, and machine tool spindles.

- Application Versatility:

Cylindrical roller bearings find wide applications in various machinery and equipment. They are commonly used in rotating machinery, such as electric motors, gearboxes, pumps, and compressors. Cylindrical roller bearings are also utilized in industries such as automotive, aerospace, construction, and mining, where they support heavy loads and provide rotational motion in critical components. The versatility of cylindrical roller bearings makes them a preferred choice across different sectors.

- Alignment and Compensation:

Cylindrical roller bearings have the ability to accommodate slight misalignments between the inner and outer rings. This feature allows for easier installation and helps compensate for mounting errors or shaft deflections during operation. The axial displacement capability of cylindrical roller bearings can also assist in thermal expansion or contraction of the shaft and housing. This ability to handle misalignment and axial displacement contributes to the overall reliability and longevity of machinery.

- Durability and Longevity:

Cylindrical roller bearings are designed to withstand heavy loads, shocks, and vibrations encountered in various applications. They are manufactured with high-quality materials and undergo stringent quality control processes to ensure durability and reliability. Proper lubrication and maintenance further enhance their longevity and performance, making cylindrical roller bearings a dependable choice for demanding industrial environments.

In summary, cylindrical roller bearings offer significant advantages in terms of high radial load capacity, moderate thrust load capacity, high-speed capability, application versatility, alignment and compensation capabilities, and durability. These advantages make cylindrical roller bearings well-suited for a wide range of machinery applications, contributing to efficient operation, reduced downtime, and extended service life.

editor by CX 2024-05-03