Product Description

ACTIVE-POWER INDUSTRIES Cylindrical Roller Bearings Fcd4872290 China Suppliers NJ1008M Thrust Cylindrical Roller Bearing

Product Description

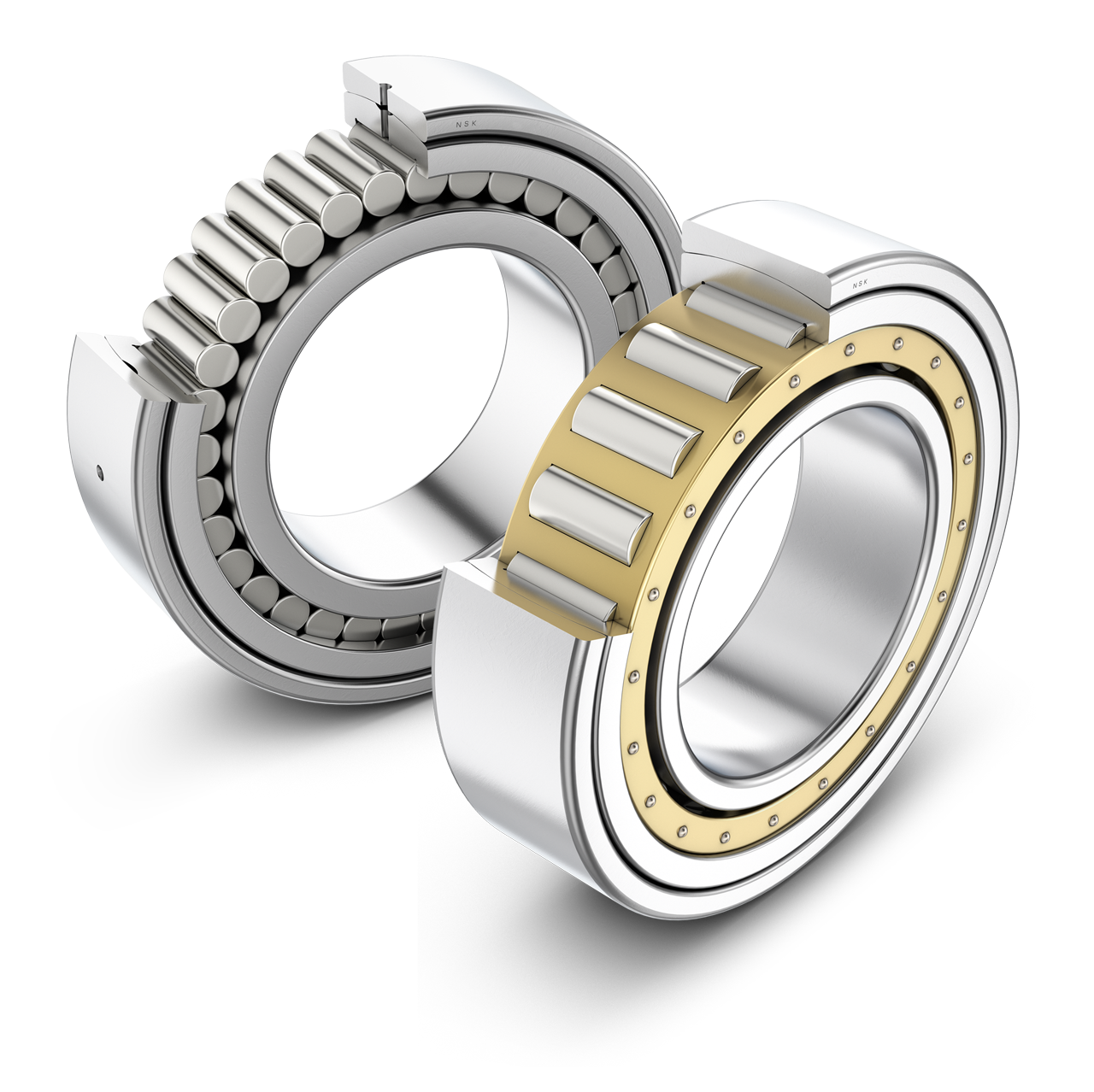

The internal structure of the cylindrical roller bearing adopts rollers arranged in parallel, and spacers or spacers are installed between the rollers, which can prevent the rollers from tilting or friction between the rollers, and effectively prevent the increase of the rotational torque.

According to whether the ring has ribs, it can be divided into single-row cylindrical roller bearings such as NU, NJ, NUP, N, NF, and double-row cylindrical roller bearings such as NNU and NN. The bearing has a detachable inner ring and outer ring.

Features

1. The rollers and the raceway are in line contact or trimmed line contact, with large radial bearing capacity, suitable for bearing heavy loads and impact loads.

2. The friction coefficient is small, suitable for high speed, and the limit speed is close to that of deep groove ball bearings.

3. N-type and NU-type can move axially, can adapt to changes in the relative position of the shaft and the shell caused by thermal expansion or installation errors, and can be used as free-end supports.

4. The processing requirements for the shaft or seat hole are relatively high. After the bearing is installed, the relative deviation of the axis of the outer ring must be strictly controlled to avoid contact stress concentration.

5. The inner or outer ring can be separated for easy installation and removal

Application:

Large and medium-sized electric motors, rolling stock, machine tool spindles, internal combustion engines, generators, gas turbines, gearboxes, rolling mills, vibrating screens, lifting and transporting machinery, etc.

Product Parameters

| Product Name | Cylindrical Roller Bearing |

| Structure | Cylindrical Roller Bearing |

| Applicable Industries | Machinery repair shop, manufacturing plant, automobile manufacturing, agricultural machinery |

| Size | 30mm-800mm |

| Accuracy Grade | P0 P6 P5 P4 |

| Seal Type | Open |

| Retainer Type | Copper / Nylon / Steel |

| Origin | ZheJiang , China |

| Service | OEM / ODM or customer logo is acceptable |

| Cylindrical Roller Bearing | |||

| NU106M | NU202M | N304E | NJ4050 |

| NU1007M | NJ202M | NU304 | N4050 |

| NJ1007M | N203E | NJ304E | N407M |

| N1008M | NU203E | N305 | N408M |

| NU1008M | NJ203E | NF305 | N409M |

| NJ1008M | NJ203E | NU305 | NJ410 |

| NU1009M | N204E | NJ305 | NU414M |

| NU1571M | NU204E | N306 | NJ414M |

| NJ1571M | NJ204E | NU306E | N416M |

| NU1011M | N205E | NJ306E | N417M |

| NJ1011M | NF205 | N307 | NU417M |

| NU1012M | NU205E | NF307EVNU307 | NJ417M |

| NJ1012M | NJ208E | NU307M | NU418M |

| NU1013M | NCL205V | NJ307M | N2310EM |

| NJ1013M | N2066E | N308EM | NU2310E |

| N1014M | NF206E | NF308EM | NJ2310E |

| NU1014M | NU206E | NU308EM | NU2311 |

| NJ1014M | NJ206E | NJ308EM | NJ2311 |

| NU1015M | NCL206V | N309E | N2312E |

| NJ1015M | N207 | NF309E | NU2312E |

| NU1016M | NF207E | NU309E | NJ2312E |

| NJ1016M | NU207 | NJ309E | NJ2314E |

| NU1017M | NJ207 | N310E | N2315EM |

| NJ1017M | N208 | N310EM | NU2315E |

| NU1018M | NJ208E | NF310E | NJ2315E |

| NJ1018M | N209E | NU310E | N2316EM |

| NU1019M | NF208E | NJ310E | NU2316E |

| NJ1019M | NU209E | N311E | NJ2316E |

| NU1571M | NJ209E | NU311E | NU2317E |

| NJ1571M | N210E | NJ311E | NJ2317E |

| NJ1571M | NF210E | NJ311E | N2318EM |

| NU1571M | NU210E | N312E | NU2318E |

| NJ1571M | N211E | NF312E | NJ2318E |

| NU1026M | NF211E | NU312E | NU2319E |

| NJ1026M | NU211E | NJ312E | NJ2319E |

| NU1571M | NJ211E | N313E | N2320EM |

| NJ1571M | N212 | NF313E | N2322EM |

| NU1030M | NU212 | NU313E | NU2322EM |

| NJ1030M | NJ212E | NJ313E | NJ2322EM |

| NU1032M | N213E | NUP313ENV | |

| NJ1032M | NU213E | N314E | |

| NU1034M | NJ213E | NF314E | |

| NU10136EM | N214E | NU314EM | |

| NJ1036EM | NF214E | NJ314E | |

| NJ1038M | NU214E | N315E | |

| NJ1038M | NJ214E | NU315E | |

| NU1040M | N215E | NJ315E | |

| NJ1040M | NF215E | N316E | |

| NU1052M | NU215E | NU316E | |

| NJ1052M | NJ215E | NJ316E | |

| N216 | N317E | ||

| NU216 | NU317E | ||

| NJ216 | NJ317E | ||

| N217E | N318E | ||

| NU217E | NU318E | ||

| NJ217E | NJ318E | ||

| N218E | N319E319EM | ||

| NU218E | NU319EM | ||

| NJ218E | NJ319EM | ||

| N219 | N320EM | ||

| NU219 | NU320EM | ||

| NJ219 | NJ320EM | ||

| N220E | NU321EM | ||

| NU222E | NJ321EM | ||

| NJ220E | NJ321E | ||

| N222EMK | N322E | ||

| NJ222E | NU322EM | ||

| N224E | NJ322E | ||

| NJ224E | N324E | ||

| N226E | NU324E | ||

| NF226EM | NJ324E | ||

| NU226E | N326EM | ||

| NJ226E | NU326EM | ||

| NU228E | NJ326EM | ||

| NU228E | N328EM | ||

| NJ228E | NU328EM | ||

| N230EM | NJ328EM | ||

| NU230E | N332EM | ||

| NJ230E | NU332EM | ||

| N232E | NJ332EM | ||

| NU232E | N334EM | ||

| NJ232E | NU334EM | ||

| N234E | NJ334EM | ||

| NU234E | N336EM | ||

| NJ234E | NU336EM | ||

| N236E | NJ336EM | ||

| NU236E | N344EM | ||

| NJ236E | NU344EM | ||

| N238E | NJ344EM | ||

| NU238E | |||

| NJ238E | |||

| N240EM | |||

| NJ240EM | |||

| N244EM | |||

| NU244EM | |||

| NJ244EM | |||

Company Profile

HangZhou Active-Power Industrial. is located in HangZhou, ZheJiang , China. The factory has been committed to the production research and development of bearings for more than 20 years. We support OEM and ODM bearing customization.

The main products are: Deep Groove Ball Bearing Taper Roller Bearing Tapered Roller Bearing Auto Wheel Hub Bearing Cylindrical Roller Bearing Spherical Roller Bearing Motor Bearing Needle Roller Bearing Angular Contact Ball Bearing.

FAQ

Q1:What is your Before-sales Service?

1>. Offer to bear related consultation about technology and application;

2>.Help customers with bearing choice, clearance configuration, product” life, and reliability analysis;

3>. Offer highly cost-effective and complete solution program according to site conditions;

4>. Offer localized program on introduced equipment to save running cost

Q2: What is your After-sales Service?

1>. Offer training about bearing installation and maintenance;

2>.Help customers with trouble diagnosis and failure analysis;

3>. Visit customers regularly and feedback on their rational suggestions and requirements to the company.

Q3: How about your company’s strength?

1>.FREE SAMPLES:

contact us by email or trade manager, we will send the free samples according to your request.

2>. World-Class Bearing:

We provide our customers with all types of indigenous roller bearings of world-class quality.

3>.OEM or Non-Stand Bearings:

Any requirement for Non-standard roller bearings is Easily Fulfilled by us due to our vast knowledge and links in the industry.

4>.Genuine products With Excellent Quality:

The company has always proved the 100% quality products it provides with genuine intent.

5>. After-Sales Service and Technical Assistance:

The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

6>.Quick Delivery:

The company provides just-in-time delivery with its streamlined supply chain.

7>.Cost Saving:

We provide long-life, shock-resistant, and high-reliability roller bearings with excellent quality and better performance.

Resulting in increased cost savings.

Q4: What will we do if you are not satisfied with the product?

A: If have any abnormal, Please contact us at the first time, and we will immediately process

Q5: How long will you respond to our problems?

A: We will respond within 1 hour. 24 hours to solve your problem

Q6: Is optional lubrication provided?

A: We can offer a wide range of oils and greases for a variety of applications. Please contact our engineer for technical

assistance with any special requirements

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Multi-column |

| Outer Dimension: | Micro(≤26mm) |

| Material: | Rubber |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Thrust Bearing |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do Tapered Roller Bearings Enhance the Performance of Gearboxes and Transmissions?

Tapered roller bearings play a crucial role in enhancing the performance, efficiency, and reliability of gearboxes and transmissions in various applications, including automotive, industrial machinery, and power generation. These bearings are specifically designed to handle radial and axial loads, making them ideal for supporting rotating shafts and gear assemblies. Here’s how tapered roller bearings contribute to the performance of gearboxes and transmissions:

- Load Distribution:

Gearboxes and transmissions experience a combination of radial and axial loads due to gear meshing and torque transmission. Tapered roller bearings distribute these loads evenly across the rolling elements, minimizing stress concentrations and ensuring reliable operation.

- Axial Load Handling:

As gears transmit torque, axial forces are generated. Tapered roller bearings are capable of handling both radial and axial loads, ensuring stable and controlled motion while accommodating the forces generated by gear engagement.

- Reduced Friction and Wear:

Tapered roller bearings are designed with precision-matched rollers and raceways, reducing friction and wear. This results in smoother gear rotation, reduced heat generation, and extended component life.

- Optimized Axial Preload:

In certain applications, axial preload can be applied to eliminate internal clearance and enhance gear meshing performance. Tapered roller bearings allow for controlled axial preload adjustment, ensuring proper gear engagement and reducing backlash.

- Accurate Gear Alignment:

Tapered roller bearings aid in maintaining accurate gear alignment and positioning. This is critical for achieving smooth gear transitions, preventing misalignment-related wear, and reducing noise and vibration.

- Efficient Power Transmission:

Efficient gear operation is crucial for transmitting power from the input to the output shaft. Tapered roller bearings minimize energy losses due to friction, allowing more power to be efficiently transmitted through the gearbox or transmission.

- High-Speed Capability:

Tapered roller bearings are suitable for high-speed applications, making them suitable for gearboxes and transmissions where rapid gear shifts or changes in rotational speed are required.

- Reduced Noise and Vibration:

The smooth operation of tapered roller bearings contributes to reduced noise and vibration in gearboxes and transmissions. This leads to a quieter and more comfortable user experience.

- Long Service Life:

The robust design and high-quality materials used in tapered roller bearings enhance their durability and resistance to wear. This extends the service life of gearboxes and transmissions, reducing maintenance and replacement frequency.

- Enhanced Gearbox Performance:

Tapered roller bearings optimize the performance of gearboxes and transmissions, contributing to smoother gear shifting, improved fuel efficiency, better power transmission, and overall enhanced drivetrain performance.

Overall, tapered roller bearings are essential components that enhance the efficiency, reliability, and performance of gearboxes and transmissions in a wide range of applications.

What are the potential challenges or limitations of using cylindrical roller bearings in specific industries?

While cylindrical roller bearings offer numerous advantages, there are also certain challenges and limitations associated with their use in specific industries. Let’s explore some of these potential challenges:

- High-Speed Applications:

In industries that require high-speed rotating machinery, such as machine tools or centrifugal compressors, the limitations of cylindrical roller bearings become more pronounced. At high speeds, factors like centrifugal forces, increased operating temperatures, and the potential for roller skidding can impact the bearing’s performance. Special design considerations, such as optimized cage designs, precision manufacturing, and proper lubrication, are necessary to overcome these challenges and ensure reliable operation at high speeds.

- High-Temperature Environments:

In industries like steel production, glass manufacturing, or certain types of furnaces, the operating temperatures can exceed the limits of standard cylindrical roller bearings. High temperatures can cause dimensional changes, affect the lubricant properties, and lead to accelerated wear or premature failure of the bearing components. To address this limitation, specialized high-temperature bearings with heat-resistant materials, advanced lubrication systems, and appropriate sealing mechanisms are required.

- Heavy Load and Shock Loads:

Industries involving heavy machinery, such as construction, mining, or material handling, often subject cylindrical roller bearings to extremely heavy loads or sudden shock loads. These conditions can lead to increased stress, fatigue, or even permanent deformation of the bearing components. To overcome these challenges, bearings with higher load-carrying capacities, robust designs, and enhanced fatigue resistance are necessary. Additionally, proper maintenance practices and regular monitoring are crucial to detect any signs of excessive load or potential failure.

- Contamination and Harsh Environments:

In industries characterized by harsh operating environments, such as agriculture, forestry, or automotive manufacturing, cylindrical roller bearings can face challenges related to contamination, moisture, or exposure to abrasive particles. Contaminants can accelerate wear, cause damage to the bearing surfaces, or impair the lubrication effectiveness. Sealing solutions, effective maintenance practices, and the selection of appropriate bearing materials are essential to mitigate these challenges and ensure reliable performance in such environments.

- Space Limitations:

In certain industries like aerospace or robotics, where space is limited and compact designs are required, the size and dimensions of cylindrical roller bearings can pose challenges. Finding suitable bearing sizes that meet the specific space constraints while still fulfilling the load and performance requirements can be a limitation. In such cases, alternative bearing types or customized bearing solutions may be explored to overcome the space limitations.

It’s important to note that while there may be challenges or limitations associated with using cylindrical roller bearings in specific industries, advancements in bearing technology, materials, and design continue to address and overcome many of these limitations. Consulting with bearing manufacturers, considering application-specific requirements, and implementing appropriate maintenance practices can help mitigate these challenges and ensure the successful use of cylindrical roller bearings in a wide range of industries.

Can you explain the design and structure of cylindrical roller bearings?

Cylindrical roller bearings have a specific design and structure that enables them to handle high radial loads and moderate thrust loads. Let’s explore the key components and features of cylindrical roller bearings:

- Inner and Outer Rings:

The inner and outer rings of cylindrical roller bearings are typically made of high-quality bearing steel. The inner ring is mounted on the rotating shaft, while the outer ring is usually mounted in a stationary housing. The rings are precision-machined with raceways that serve as the contact surfaces for the cylindrical rollers.

- Cylindrical Rollers:

Cylindrical rollers are the main load-carrying components of the bearing. They are cylindrical in shape and have a high length-to-diameter ratio. The rollers are precision-ground to ensure close tolerances and uniform size distribution. The large contact area between the rollers and the raceways allows for efficient load distribution and reduced stresses.

- Cage:

A cage, also known as a separator, is used to keep the cylindrical rollers evenly spaced and prevent them from coming into contact with each other. The cage is typically made of steel or other materials such as brass or polyamide (nylon). It provides guidance and retains the rollers in position during operation, ensuring smooth rolling motion and preventing roller skewing or jamming.

- Flanges:

Cylindrical roller bearings may have flanges on the inner or outer rings or both. Flanges are raised edges or shoulders that provide axial guidance and help in locating the bearing in the axial direction. The presence of flanges can also improve the overall rigidity and axial load-carrying capacity of the bearing.

- Internal Clearance:

The internal clearance of cylindrical roller bearings refers to the space between the rollers and raceways when there is no external load applied. It affects the bearing’s thermal expansion, running accuracy, and ability to accommodate misalignment or axial displacement. Different levels of internal clearance are available to suit specific application requirements.

- Lubrication:

Cylindrical roller bearings require proper lubrication to minimize friction, reduce wear, and dissipate heat generated during operation. Lubrication helps to maintain the separation between the rolling elements and raceways, preventing metal-to-metal contact and minimizing the risk of premature failure. Common lubrication methods include grease lubrication and oil lubrication.

- Sealing and Protection:

Cylindrical roller bearings can be equipped with various types of seals or shields to prevent the ingress of contaminants and retain lubrication. These seals and shields help to extend the bearing’s service life and maintain its performance by providing protection against moisture, dust, and other external factors that could cause damage or deterioration.

Overall, the design and structure of cylindrical roller bearings allow them to efficiently handle radial loads and moderate thrust loads. The combination of inner and outer rings, cylindrical rollers, cage, flanges, internal clearance, lubrication, and sealing work together to provide reliable and smooth rotational motion in machinery applications.

editor by CX 2024-04-29