Product Description

RU42 Cross Cylindrical Roller Bearings Introduction:

RU42 Cross Cylindrical Roller Bearings are the overall structure of the inner and outer rings. Compared with the ERBH model, there are mounting holes on the end face, which is convient for the structural design appliction of end face installation. It can be installed and used without the shaft of bearing seat.

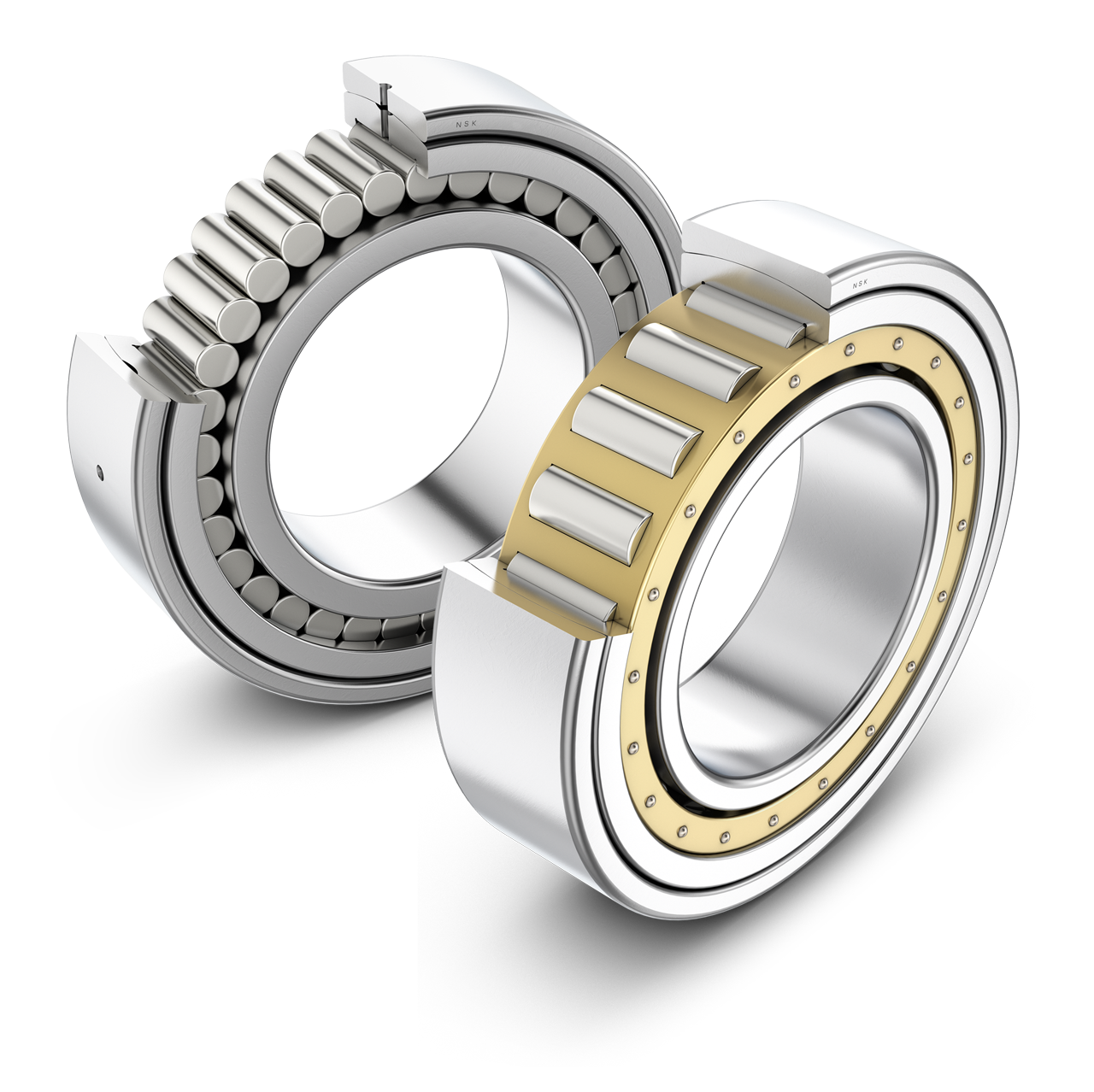

RU42 Cross Cylindrical Roller Bearings Display:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Samples: |

US$ 40/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do Tapered Roller Bearings Enhance the Performance of Gearboxes and Transmissions?

Tapered roller bearings play a crucial role in enhancing the performance, efficiency, and reliability of gearboxes and transmissions in various applications, including automotive, industrial machinery, and power generation. These bearings are specifically designed to handle radial and axial loads, making them ideal for supporting rotating shafts and gear assemblies. Here’s how tapered roller bearings contribute to the performance of gearboxes and transmissions:

- Load Distribution:

Gearboxes and transmissions experience a combination of radial and axial loads due to gear meshing and torque transmission. Tapered roller bearings distribute these loads evenly across the rolling elements, minimizing stress concentrations and ensuring reliable operation.

- Axial Load Handling:

As gears transmit torque, axial forces are generated. Tapered roller bearings are capable of handling both radial and axial loads, ensuring stable and controlled motion while accommodating the forces generated by gear engagement.

- Reduced Friction and Wear:

Tapered roller bearings are designed with precision-matched rollers and raceways, reducing friction and wear. This results in smoother gear rotation, reduced heat generation, and extended component life.

- Optimized Axial Preload:

In certain applications, axial preload can be applied to eliminate internal clearance and enhance gear meshing performance. Tapered roller bearings allow for controlled axial preload adjustment, ensuring proper gear engagement and reducing backlash.

- Accurate Gear Alignment:

Tapered roller bearings aid in maintaining accurate gear alignment and positioning. This is critical for achieving smooth gear transitions, preventing misalignment-related wear, and reducing noise and vibration.

- Efficient Power Transmission:

Efficient gear operation is crucial for transmitting power from the input to the output shaft. Tapered roller bearings minimize energy losses due to friction, allowing more power to be efficiently transmitted through the gearbox or transmission.

- High-Speed Capability:

Tapered roller bearings are suitable for high-speed applications, making them suitable for gearboxes and transmissions where rapid gear shifts or changes in rotational speed are required.

- Reduced Noise and Vibration:

The smooth operation of tapered roller bearings contributes to reduced noise and vibration in gearboxes and transmissions. This leads to a quieter and more comfortable user experience.

- Long Service Life:

The robust design and high-quality materials used in tapered roller bearings enhance their durability and resistance to wear. This extends the service life of gearboxes and transmissions, reducing maintenance and replacement frequency.

- Enhanced Gearbox Performance:

Tapered roller bearings optimize the performance of gearboxes and transmissions, contributing to smoother gear shifting, improved fuel efficiency, better power transmission, and overall enhanced drivetrain performance.

Overall, tapered roller bearings are essential components that enhance the efficiency, reliability, and performance of gearboxes and transmissions in a wide range of applications.

What are the potential challenges or limitations of using cylindrical roller bearings in specific industries?

While cylindrical roller bearings offer numerous advantages, there are also certain challenges and limitations associated with their use in specific industries. Let’s explore some of these potential challenges:

- High-Speed Applications:

In industries that require high-speed rotating machinery, such as machine tools or centrifugal compressors, the limitations of cylindrical roller bearings become more pronounced. At high speeds, factors like centrifugal forces, increased operating temperatures, and the potential for roller skidding can impact the bearing’s performance. Special design considerations, such as optimized cage designs, precision manufacturing, and proper lubrication, are necessary to overcome these challenges and ensure reliable operation at high speeds.

- High-Temperature Environments:

In industries like steel production, glass manufacturing, or certain types of furnaces, the operating temperatures can exceed the limits of standard cylindrical roller bearings. High temperatures can cause dimensional changes, affect the lubricant properties, and lead to accelerated wear or premature failure of the bearing components. To address this limitation, specialized high-temperature bearings with heat-resistant materials, advanced lubrication systems, and appropriate sealing mechanisms are required.

- Heavy Load and Shock Loads:

Industries involving heavy machinery, such as construction, mining, or material handling, often subject cylindrical roller bearings to extremely heavy loads or sudden shock loads. These conditions can lead to increased stress, fatigue, or even permanent deformation of the bearing components. To overcome these challenges, bearings with higher load-carrying capacities, robust designs, and enhanced fatigue resistance are necessary. Additionally, proper maintenance practices and regular monitoring are crucial to detect any signs of excessive load or potential failure.

- Contamination and Harsh Environments:

In industries characterized by harsh operating environments, such as agriculture, forestry, or automotive manufacturing, cylindrical roller bearings can face challenges related to contamination, moisture, or exposure to abrasive particles. Contaminants can accelerate wear, cause damage to the bearing surfaces, or impair the lubrication effectiveness. Sealing solutions, effective maintenance practices, and the selection of appropriate bearing materials are essential to mitigate these challenges and ensure reliable performance in such environments.

- Space Limitations:

In certain industries like aerospace or robotics, where space is limited and compact designs are required, the size and dimensions of cylindrical roller bearings can pose challenges. Finding suitable bearing sizes that meet the specific space constraints while still fulfilling the load and performance requirements can be a limitation. In such cases, alternative bearing types or customized bearing solutions may be explored to overcome the space limitations.

It’s important to note that while there may be challenges or limitations associated with using cylindrical roller bearings in specific industries, advancements in bearing technology, materials, and design continue to address and overcome many of these limitations. Consulting with bearing manufacturers, considering application-specific requirements, and implementing appropriate maintenance practices can help mitigate these challenges and ensure the successful use of cylindrical roller bearings in a wide range of industries.

What are the key advantages of using cylindrical roller bearings in various applications?

Cylindrical roller bearings offer several key advantages that make them a preferred choice in various applications. Let’s explore the significant benefits of using cylindrical roller bearings:

- High Radial Load Capacity:

Cylindrical roller bearings are specifically designed to handle high radial loads. Their cylindrical roller arrangement and large contact area with the raceways enable them to distribute loads evenly along the rollers’ length. This characteristic allows cylindrical roller bearings to support heavy machinery components and handle substantial radial forces, making them suitable for applications where the primary load is radial in nature.

- Moderate Thrust Load Capacity:

While their primary function is to carry radial loads, cylindrical roller bearings can also accommodate moderate axial loads. The arrangement of the cylindrical rollers and their contact angle with the raceways enables these bearings to handle limited thrust loads. However, it’s important to note that for applications with predominantly axial loads, other types of bearings, such as thrust bearings, may be more suitable.

- High-Speed Capability:

Cylindrical roller bearings can operate at high speeds, depending on their design and internal clearance. Factors such as cage material, roller design, and lubrication play a role in determining the maximum allowable speed. The ability to operate at high speeds makes cylindrical roller bearings suitable for applications that require efficient and reliable rotation, such as electric motors, gearboxes, and machine tool spindles.

- Application Versatility:

Cylindrical roller bearings find wide applications in various machinery and equipment. They are commonly used in rotating machinery, such as electric motors, gearboxes, pumps, and compressors. Cylindrical roller bearings are also utilized in industries such as automotive, aerospace, construction, and mining, where they support heavy loads and provide rotational motion in critical components. The versatility of cylindrical roller bearings makes them a preferred choice across different sectors.

- Alignment and Compensation:

Cylindrical roller bearings have the ability to accommodate slight misalignments between the inner and outer rings. This feature allows for easier installation and helps compensate for mounting errors or shaft deflections during operation. The axial displacement capability of cylindrical roller bearings can also assist in thermal expansion or contraction of the shaft and housing. This ability to handle misalignment and axial displacement contributes to the overall reliability and longevity of machinery.

- Durability and Longevity:

Cylindrical roller bearings are designed to withstand heavy loads, shocks, and vibrations encountered in various applications. They are manufactured with high-quality materials and undergo stringent quality control processes to ensure durability and reliability. Proper lubrication and maintenance further enhance their longevity and performance, making cylindrical roller bearings a dependable choice for demanding industrial environments.

In summary, cylindrical roller bearings offer significant advantages in terms of high radial load capacity, moderate thrust load capacity, high-speed capability, application versatility, alignment and compensation capabilities, and durability. These advantages make cylindrical roller bearings well-suited for a wide range of machinery applications, contributing to efficient operation, reduced downtime, and extended service life.

editor by CX 2024-04-24