Product Description

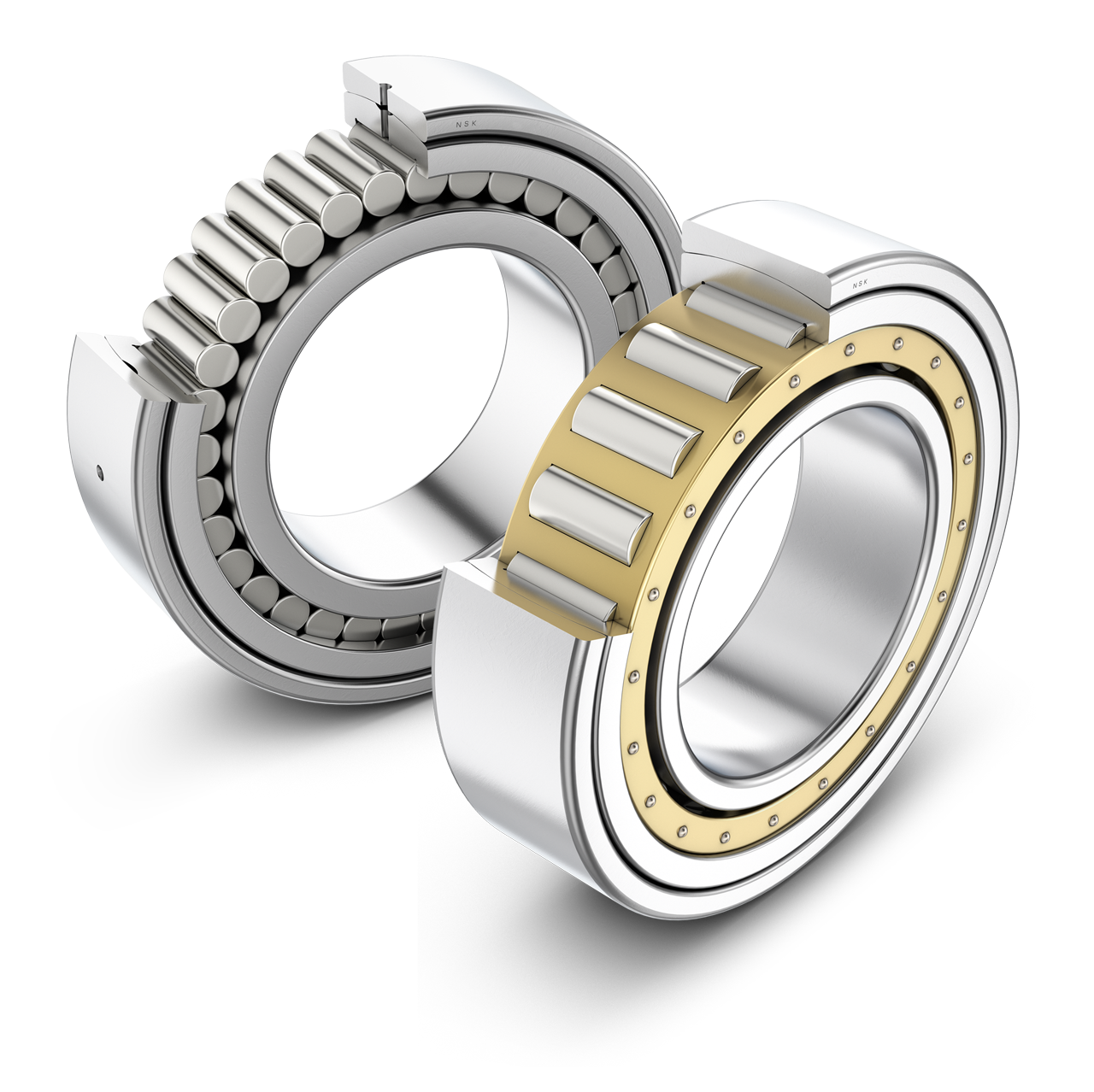

Feature: Cylindrical roller bearing

Single row cylindrical roller bearing feature:

Tape NU and type N allow shaft moving in axial direction within limits,applicable to use as free end.

Type NJ and type NF can carry certain extent one-way axial load.Type NUP and type NH can carry certain extent both-way axial load.

Main dimension of type E cylindrical roller bearing coordinate with standard, and through modifying interior specification to increase nominal load.

Double row cylindrical roller bearing feature:

Double row cylindrical roller bearing have cylindrical hole and tapered hole type,tapered bore bearing can get needed internal clearance by self-aligning the depth of thrusting in.

Besides,there are bearing whose outer ring with oil hole and oil tank,it’s nominal type code has a post position assistant code “W”.

The type bearing has strong fixity resisting reversal load,mainly applicable to chief shaft of machine tool,etc.

Types of Cylindrical roller bearing

N series cylindrical roller bearing design The inner ring has 2 integral flanges and the outer ring is without flanges. Axial displacement of the shaft with respect to the housing can be accommodated in both directions within the bearing itself. The bearings are therefore used as non-locating bearings.

NU series cylindrical roller bearing design The outer ring of bearings of the NU design has 2 integral flanges and the inner ring is without flanges. Axial displacement of the shaft with respect to the housing can be accommodated in both directions within the bearing itself.

NJ series cylindrical roller bearing design The outer ring has 2 integral flanges and the inner ring 1 integral flange. The bearings are therefore suitable for the axial location of a shaft in 1 direction.

NF series cylindrical roller bearing design The outer ring has 1 integral flange and the inner ring 2 integral flanges.

NP series cylindrical roller bearing design The outer ring has 1 integral flange and 1 non-integral flange in the form of a loose flange ring and the inner ring 2 integral flanges.

NUP series cylindrical roller bearing design The outer ring has 2 integral flanges and the inner ring 1 integral flange and 1 non-integral flange in the form of a loose flange ring. The bearings can be used as locating bearings, i.e. they can provide axial location for a shaft in both directions.

RN series cylindrical roller bearing design No outer ring and the inner ring 2 integral flanges.

Cylindrical roller bearing Specification:

| Seals Types | OPEN |

| Vibration Level | Z1V1,Z2V2,Z3V3 |

| Clearance | C2,C0,C3,C4,C5 |

| Tolerance Codes | ABEC-1,ABEC-3,ABEC-5 |

| Materral | GCr15-China/AISI52100-USA/Din100Cr6-Germany |

| MOQ | 1Set at least |

| Delivery Time | 15-45 days after contract |

| Payment Terms | TT/PAPAL/WESTERN UNION |

| Package | Tube package+outer carton+pallets;Single box+outer carton+pallets;Tube pavkge+middle box+outer carton+pallets;According to your requirement |

A Part of Cylindrical Roller Bearings:

| N/Nu/NF/Nj/Nup/Ncl/Rn/Rnu Series | |||

| NU207(M) | NJ202(E/EM) | NF202 | NUP210E |

| NU208(M) | NJ203(E/EM) | NF203 | NUP211E |

| NU210(M) | NJ204(E/EM) | NF204 | NUP212E |

| NU211(M) | NJ205(E/EM) | NF205 | NUP213E |

| NU212(M) | NJ206(E/EM) | NF206 | NUP214E |

| NU213(M) | NJ207(E/EM) | NF207 | NUP215E |

| NU214(M) | NJ208(E/EM) | NF208 | NUP216E |

| NU215(M) | NJ209(E/EM) | NF209 | NUP217E |

| NU216(M) | NJ310EM | NF306(EM/ETN) | NUP218E |

| NU217(M) | NJ311EM | NF307(EM/ETN) | NUP219E |

| NU218(M) | NJ313EM | NF308(EM/ETN) | NUP2205E |

| NU219(M) | NJ313EM | NF309(EM/ETN) | NUP2206E |

| NU220(M) | NJ314EM | NF2210EM | NUP2207E |

| NU221(M) | NJ315EM | NF2211EM | NUP2208E |

| NU222(M) | NJ316EM | NF2212EM | NUP2209E |

| NU224(M) | NJ317EM | NF2213EM | NUP2210E |

| NU226(M) | NJ318EM | NF2214EM | NUP2211E |

| NU228(M) | NJ319EM | NF2215EM | NUP2212E |

| NU230(M) | NJ420 | NF2216EM | NUP2213E |

| NU232(M) | NJ421 | NF2217EM | NUP2214E |

| NU234(M) | NJ422 | NF2218EM | NUP2215E |

| NU236(M) | NJ423 | NF2219EM | NUP2216E |

| NU238(M) | NJ424 | NF2220EM | NUP2217E |

| NU240(M) | NJ425 | NF2230 | NUP2218E |

| NU244(M) | NJ426 | NF2232 | NUP2219E |

| NU308(M) | NJ427 | NF2234 | NUP2220E |

| NU309(M) | NJ428 | NF2306 | NUP2305E |

| NU310(M) | NJ2208E | NF2307 | NUP2306E |

| NU311(M) | NJ2209E | NF2308 | NUP2307E |

| NU312(M) | NJ2210E | NF2309 | NUP2308E |

| NU313(M) | NJ2211E | NF2310 | NUP2309E |

| NU314(M) | NJ2212E | NF2311 | NUP2310E |

| NU315(M) | NJ2213E | NF2312 | NUP2311E |

| NU316(M) | NJ2214E | NF2313 | NUP2312E |

| NU317(M) | NJ2215E | NF2314 | NUP2313E |

| NU318(M) | NJ2216E | NF2315 | NUP2314E |

| NU319(M) | NJ2217E | NF2316 | NUP2315 |

| NU320(M) | NJ2218E | NF2317 | NUP2316 |

| NU321(M) | NJ2219E | NF2318 | NUP2317 |

| NU322(M) | NJ2220E | NF2319 | NUP2318 |

| NU323(M) | NJ2222 | NF2320 | NUP2319 |

| NU324(M) | NJ2224 | NF2322 | NUP2320 |

| NU326(M) | NJ2226 | NF2324 | NUP2322 |

| NU332(M) | NF2326 | NUP2324 | |

| NU334(M) | NF2328 | NUP2326 | |

Our Company

As a comprehensive industrial enterprise that integrates R & D and sales services, with over 20 years’ experience, especially the guaranteed supplier of China Manufacturing Network, our factory covers an area of 10,000 square meters, which enables very quick delivery.

Owning the most advanced CNC automatic production line, automatic assembly line, and a varied of testing equipment, our bearings mainly cover NSK, NTN, KOYO, NACHI, THK etc., which meets all low noise, low vibration, low friction, high precision, high sealed, high turning speed and long life requests.

FAQ

SAMPLES

1.Samples quantity: 1-10 pcs are available.

2.Free samples: It depends on the model NO., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3.It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1.MOQ: 10 pcs mix different standard bearings.

2.MOQ: 5000 pcs customized your brand bearings.

OEM POLICY

1.We can printing your brand (logo,artwork)on the shield or laser engraving your brand on the shield.

2.We can custom your packaging according to your design

3.All copyright own by clients and we promised don’t disclose any info.

SUPORT

Please visit our 1Xihu (West Lake) Dis.in bearings website, we strongly encourage that you can communicate with us through email, thanks!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Bearing Steel |

| Spherical: | Aligning Bearings |

| Load Direction: | Radial Bearing |

| Customization: |

Available

| Customized Request |

|---|

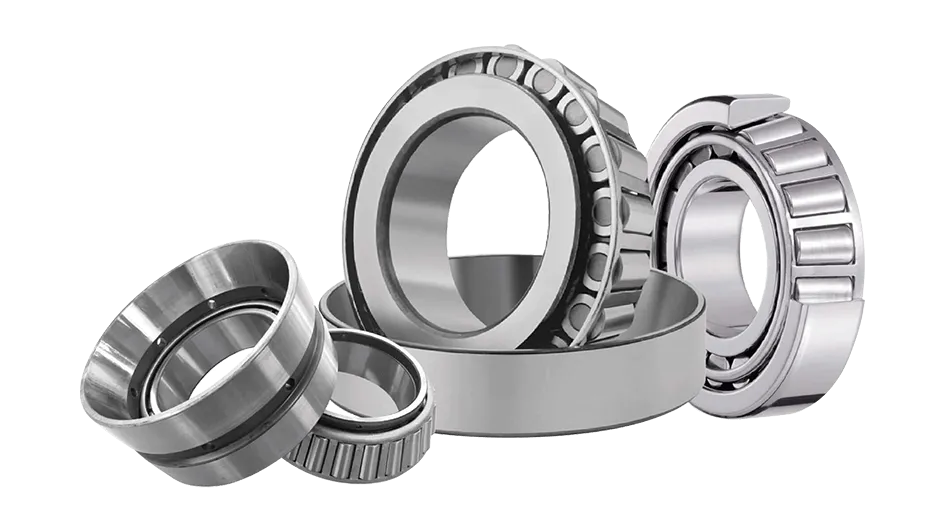

What are the Challenges Associated with Thermal Expansion in Tapered Roller Bearings?

Thermal expansion presents several challenges in tapered roller bearings, particularly in industrial and high-speed applications. As the bearing components heat up during operation, they expand, which can impact the bearing’s performance, longevity, and overall operation. Here are the challenges associated with thermal expansion in tapered roller bearings:

- Internal Clearance Reduction:

As the bearing components heat up, their dimensions increase due to thermal expansion. This reduction in internal clearance can lead to increased friction, higher operating temperatures, and even binding of the rolling elements.

- Lubrication Concerns:

Thermal expansion can affect the distribution and viscosity of the lubricant within the bearing. If the lubricant thins out due to temperature rise, it may not provide adequate protection against friction and wear, potentially leading to premature failure.

- Increased Friction and Wear:

With reduced internal clearance and potential changes in lubrication properties, the bearing is more susceptible to increased friction and wear. This can result in accelerated wear of the rolling elements, raceways, and cage.

- Higher Operating Temperatures:

Thermal expansion contributes to elevated operating temperatures within the bearing assembly. Excessive heat generation can degrade the lubricant, weaken bearing materials, and reduce overall efficiency.

- Alignment Issues:

Temperature-related expansion can lead to misalignment between bearing components, causing uneven loading and potential damage to the rollers and raceways. This misalignment can also lead to increased vibration and noise.

- Variability in Fit and Clearance:

Components within the bearing may expand at different rates due to variations in material properties. This can result in changes in fit and clearance between components, affecting the overall stability and performance of the bearing.

- Impact on Preload:

If a bearing is preloaded to eliminate internal clearance, thermal expansion can significantly affect preload values. This can lead to altered load distribution, increased stress on components, and potential bearing damage.

- Performance Inconsistencies:

Thermal expansion can introduce inconsistencies in bearing performance, especially during transient operating conditions where temperature changes occur rapidly.

- Limitations in High-Speed Applications:

In high-speed applications, the rapid temperature rise due to friction and heat generation can exacerbate the challenges of thermal expansion, necessitating careful design and lubrication strategies.

- Design and Material Considerations:

Manufacturers must carefully consider the materials and design aspects of tapered roller bearings to account for thermal expansion effects. This may involve selecting materials with suitable thermal properties and optimizing internal clearances.

Managing thermal expansion challenges requires a comprehensive approach that involves proper bearing design, lubrication strategies, and monitoring of operating conditions. Addressing these challenges ensures that tapered roller bearings can perform optimally and reliably in various applications.

What are the potential challenges or limitations of using cylindrical roller bearings in specific industries?

While cylindrical roller bearings offer numerous advantages, there are also certain challenges and limitations associated with their use in specific industries. Let’s explore some of these potential challenges:

- High-Speed Applications:

In industries that require high-speed rotating machinery, such as machine tools or centrifugal compressors, the limitations of cylindrical roller bearings become more pronounced. At high speeds, factors like centrifugal forces, increased operating temperatures, and the potential for roller skidding can impact the bearing’s performance. Special design considerations, such as optimized cage designs, precision manufacturing, and proper lubrication, are necessary to overcome these challenges and ensure reliable operation at high speeds.

- High-Temperature Environments:

In industries like steel production, glass manufacturing, or certain types of furnaces, the operating temperatures can exceed the limits of standard cylindrical roller bearings. High temperatures can cause dimensional changes, affect the lubricant properties, and lead to accelerated wear or premature failure of the bearing components. To address this limitation, specialized high-temperature bearings with heat-resistant materials, advanced lubrication systems, and appropriate sealing mechanisms are required.

- Heavy Load and Shock Loads:

Industries involving heavy machinery, such as construction, mining, or material handling, often subject cylindrical roller bearings to extremely heavy loads or sudden shock loads. These conditions can lead to increased stress, fatigue, or even permanent deformation of the bearing components. To overcome these challenges, bearings with higher load-carrying capacities, robust designs, and enhanced fatigue resistance are necessary. Additionally, proper maintenance practices and regular monitoring are crucial to detect any signs of excessive load or potential failure.

- Contamination and Harsh Environments:

In industries characterized by harsh operating environments, such as agriculture, forestry, or automotive manufacturing, cylindrical roller bearings can face challenges related to contamination, moisture, or exposure to abrasive particles. Contaminants can accelerate wear, cause damage to the bearing surfaces, or impair the lubrication effectiveness. Sealing solutions, effective maintenance practices, and the selection of appropriate bearing materials are essential to mitigate these challenges and ensure reliable performance in such environments.

- Space Limitations:

In certain industries like aerospace or robotics, where space is limited and compact designs are required, the size and dimensions of cylindrical roller bearings can pose challenges. Finding suitable bearing sizes that meet the specific space constraints while still fulfilling the load and performance requirements can be a limitation. In such cases, alternative bearing types or customized bearing solutions may be explored to overcome the space limitations.

It’s important to note that while there may be challenges or limitations associated with using cylindrical roller bearings in specific industries, advancements in bearing technology, materials, and design continue to address and overcome many of these limitations. Consulting with bearing manufacturers, considering application-specific requirements, and implementing appropriate maintenance practices can help mitigate these challenges and ensure the successful use of cylindrical roller bearings in a wide range of industries.

How do cylindrical roller bearings contribute to reduced friction and heat generation?

Cylindrical roller bearings play a crucial role in reducing friction and minimizing heat generation in various applications. Let’s explore how these bearings contribute to these important factors:

- Rolling Motion:

Cylindrical roller bearings facilitate rolling motion between the inner and outer rings, as well as the cylindrical rollers. This rolling motion significantly reduces friction compared to sliding or rubbing contact. Instead of sliding against each other, the rolling elements roll smoothly over the raceways, resulting in lower frictional forces. The reduced friction helps to minimize energy loss and heat generation within the bearing.

- Precision Manufacturing:

Cylindrical roller bearings are precision-engineered components manufactured to tight tolerances. The surfaces of the rollers and raceways are carefully finished to ensure smooth and precise contact. The high precision in the bearing’s construction minimizes irregularities and imperfections that could cause increased friction and heat generation. By maintaining close tolerances, cylindrical roller bearings optimize performance and reduce frictional losses.

- Lubrication:

Proper lubrication is essential for reducing friction and heat in cylindrical roller bearings. Lubricants create a thin film between the rolling elements and raceways, separating them and minimizing direct metal-to-metal contact. This lubricant film acts as a protective barrier, reducing friction and dissipating heat generated during operation. Adequate lubrication also helps to prevent wear, corrosion, and premature failure of the bearing.

- Cage Design:

Cylindrical roller bearings often incorporate a cage or separator that spaces and guides the rollers. The cage retains the individual rollers in their proper positions, preventing them from contacting and rubbing against each other. This design feature not only maintains the integrity of the rolling elements but also reduces friction and heat generation by minimizing contact between adjacent rollers. The cage also helps to maintain proper lubricant distribution throughout the bearing.

- Efficient Load Distribution:

Cylindrical roller bearings have a line contact between the rollers and raceways, which enables efficient load distribution. The cylindrical shape of the rollers allows them to bear loads along their length, spreading the load over a larger surface area compared to other bearing types. This even distribution of the load reduces localized stresses and friction at specific contact points, resulting in reduced heat generation.

- Heat Dissipation:

Cylindrical roller bearings are typically designed with features that facilitate heat dissipation. They may incorporate special heat-treated components, such as rings and rollers, that have enhanced heat resistance properties. Additionally, the bearing design may include features such as grooves, holes, or special surface coatings to improve heat dissipation and prevent the buildup of excessive temperatures within the bearing assembly.

By minimizing friction and heat generation, cylindrical roller bearings contribute to improved efficiency, reduced energy consumption, and extended bearing life. These factors are crucial in various applications where the performance, reliability, and longevity of rotating machinery are critical considerations.

editor by CX 2024-04-25