Product Description

Product Description

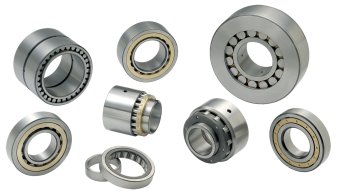

Cylindrical Roller Berings

In bearings of Cylindrical Roller Berings the cylindrical rollers are in linear contact with the raceways. They have a high radial load capacity and are suitable for high speeds.

Cylindrical roller bearings, in which either the inner or outer rings has 2 CZPT and the other ring has one, are capable of taking some axial load in 1 direction Double-row cylindrical roller bearings have high radial rigidity and are used primarily for precision machine tools. Some cylindrical roller bearings have no CZPT on either the inner or outer ring, so the rings can move axially relative to each other. These can be used as free-end bearings.

There are different types designated as NU, NJ, NUP, N, NF (for single-row cylindrical roller bearings), NNU, and NN (for double-row cylindrical roller bearings depending on the design or absence of side ribs). The outer and inner rings of all types are separable .

NU326M 32326H N326M NF326M NJ326M NUP326M

mm 18.5kg

Main items

| Bearing NO. | (mm) | Bearing No. | (mm) | ||||||

| ITEM NO. | OLD ITEM | d | D | B | Item no. | Old item | d | D | B |

| N202 | 2202 | 15 | 35 | 11 | NUP205 | 92205 | 25 | 52 | 15 |

| NF202 | 12202 | 15 | 35 | 11 | RN205 | 557105 | 25 | – | 15 |

| NU202 | 32202 | 15 | 35 | 11 | RNU205 | 292205 | – | 52 | 15 |

| NJ202 | 42202 | 15 | 35 | 11 | N2205 | 2505 | 25 | 52 | 18 |

| RN202 | 557102 | 15 | – | 11 | N2205 | 2505 | 25 | 52 | 18 |

| RNU202 | 292202 | – | 35 | 11 | NUP2205NV | E192505K | 25 | 52 | 18 |

| N203 | 2203 | 17 | 40 | 12 | LRN605/YA | 922205 | – | 52 | 15 |

| NF203 | 12203 | 17 | 40 | 12 | |||||

| NU203 | 32203 | 17 | 40 | 12 | N305 | 2305 | 25 | 62 | 17 |

| NJ203 | 42203 | 17 | 40 | 12 | NU305 | 32305 | 25 | 62 | 17 |

| RN203 | 557103 | 17 | – | 12 | NJ305 | 42305 | 25 | 62 | 17 |

| RNU203 | 292203 | – | 40 | 12 | NUP305 | 92305 | 25 | 62 | 17 |

| N204 | 2204 | 20 | 47 | 14 | RN305 | 557105 | 25 | – | 17 |

| NF204 | 12204 | 20 | 47 | 14 | NF305 | 12305 | 25 | 62 | 17 |

| NU204 | 32204 | 20 | 47 | 14 | RNU305 | 292305 | – | 62 | 17 |

| NJ204 | 42204 | 20 | 47 | 14 | NCL2305 | 102605 | 25 | 62 | 24 |

| NUP204 | 92204 | 20 | 47 | 14 | |||||

| RN204 | 557104 | 20 | – | 14 | N206 | 2206 | 30 | 62 | 16 |

| RNU204 | 292204 | – | 47 | 14 | NF206 | 12206 | 30 | 62 | 16 |

| RN-V604ENV/P6 | E392704K | – | 55 | 20 | NU206 | 32206 | 30 | 62 | 16 |

| NJ206 | 42206 | 30 | 62 | 16 | |||||

| N304 | 2304 | 20 | 52 | 15 | NUP206 | 92206 | 30 | 62 | 16 |

| NF304 | 12304 | 20 | 52 | 15 | RN206 | 557106 | 30 | – | 16 |

| NU304 | 32304 | 20 | 52 | 15 | RUN206 | 292206 | – | 62 | 16 |

| NJ304 | 42304 | 20 | 52 | 15 | NCL206 | 157106 | 30 | 62 | 16 |

| NUP304 | 92304 | 20 | 52 | 15 | |||||

| RN304 | 557104 | 20 | – | 15 | N306 | 2306 | 30 | 72 | 19 |

| RNU304 | 292304 | – | 52 | 15 | NF306 | 12306 | 30 | 72 | 19 |

| NU306 | 32306 | 30 | 72 | 19 | |||||

| N205 | 2205 | 25 | 52 | 15 | NJ306 | 42306 | 30 | 72 | 19 |

| NF205 | 12205 | 25 | 52 | 15 | NUP306 | 92306 | 30 | 72 | 19 |

| NU205 | 32205 | 25 | 52 | 15 | RN306 | 557106 | 30 | – | 19 |

| NJ205 | 42205 | 25 | 52 | 15 | |||||

| Shaft diameter (mm) | Bearing Designation | Boundary Dimensions (mm) | Basic Load Ratings (N) | Limiting Speeds (rpm) | Weight (Kg) | |||||||

| Current Designation | Original Designation | d | D | B | rsmin | r1smin | Cr Dynamic | Cor Static | Grease | Oil | ||

| 16 | SZ-4101 | 16 | 44 | 8.3 | 15700 | 18000 | 0. 0571 1 | |||||

| 17 | N203 | 2203 | 17 | 40 | 12 | 0.6 | 0.3 | 11400 | 9100 | 16000 | 19000 | 0.07800 |

| NJ203 | 42203 | 17 | 40 | 12 | 0.7 | 0.3 | 11400 | 9100 | 16000 | 19000 | 0.06900 | |

| NJ203ETN1 | 17 | 40 | 12 | 0.6 | 0.6 | 16900 | 13800 | 16000 | 19000 | 0. 0571 8 | ||

| NU203 | 32203 | 17 | 40 | 12 | 0.6 | 0.3 | 11400 | 9100 | 16000 | 19000 | 0.07000 | |

| NU203ETN1 | 17 | 40 | 12 | 0.6 | 0.3 | 16900 | 13800 | 16000 | 19000 | 0.06654 | ||

| NJ2203E | 17 | 40 | 16 | 0.6 | 0.3 | 22800 | 20300 | 13800 | 16400 | 0.09200 | ||

| 20 | N204 | 2204 | 20 | 47 | 14 | 1 | 0.6 | 15800 | 13100 | 13800 | 16400 | 0.13300 |

| NF204 | 12204 | 20 | 47 | 14 | 1 | 0.6 | 15800 | 13100 | 13800 | 16400 | 0.11000 | |

| NJ204 | 42204 | 20 | 47 | 14 | 1.1 | 0.7 | 17000 | 14400 | 13800 | 16400 | 0.14000 | |

| NU204 | 32204 | 20 | 47 | 14 | 1 | 0.6 | 15800 | 13100 | 13800 | 16400 | 0.13500 | |

| NU204/C3 | 20 | 47 | 14 | 1 | 0.6 | 14400 | 13100 | 13800 | 16400 | 0.10670 | ||

| N304 | 2304 | 20 | 52 | 15 | 1.1 | 0.6 | 21800 | 17700 | 11400 | 13800 | 0.14470 | |

| NJ304 | 42304 | 20 | 52 | 15 | 1.1 | 0.6 | 21800 | 17700 | 11400 | 13800 | 0.15750 | |

| NU304 | 32304 | 20 | 52 | 15 | 1.1 | 0.6 | 21800 | 17700 | 11400 | 13800 | 0.15190 | |

| NUP304ETN1 | 20 | 52 | 15 | 1.1 | 0.6 | 31500 | 26800 | 10600 | 13100 | 0.15582 | ||

| NJ2304ETN1 | 20 | 52 | 21 | 1.1 | 0.6 | 42000 | 38700 | 10000 | 13000 | 0.21267 | ||

| 25 | N205 | 2205 | 25 | 52 | 15 | 1 | 0.6 | 17000 | 14900 | 11400 | 13800 | 0.13280 |

| NF205 | 12205 | 25 | 52 | 15 | 1 | 0.6 | 17000 | 14900 | 11400 | 13800 | 0.13630 | |

| NJ205 | 42205 | 25 | 52 | 15 | 1 | 0.6 | 17000 | 14900 | 11400 | 13800 | 0.14840 | |

| NJ205E | 42205E | 25 | 52 | 15 | 1 | 0.6 | 29900 | 28400 | 10600 | 13100 | 0.13400 | |

| NJ205ETN1 | 25 | 52 | 15 | 1 | 0.6 | 29900 | 28400 | 10600 | 13100 | 0.13510 | ||

| NU205 | 32205 | 25 | 52 | 15 | 1 | 0.6 | 17000 | 14900 | 11400 | 13800 | 0.13300 | |

| NU205/C3 | 25 | 52 | 15 | 1 | 0.6 | 15400 | 14900 | 11400 | 13800 | 0.13300 | ||

| NU205E | 32205E | 25 | 52 | 15 | 1 | 0.6 | 29900 | 28400 | 10600 | 13100 | 0.13013 | |

| NU205ETN1 | 25 | 52 | 15 | 1 | 0.6 | 29900 | 28400 | 10600 | 13100 | 0.13107 | ||

| NU205L | 25 | 52 | 15 | 1 | 0.6 | 20300 | 18900 | 10600 | 13100 | 0.13774 | ||

| NUP205 | 92205 | 25 | 52 | 15 | 1 | 0.6 | 17000 | 14900 | 11400 | 13800 | 0.14950 | |

| NCL205 | 157105 | 25 | 52 | 15 | 1 | 0.6 | 24600 | 24300 | 10600 | 13100 | 0.14500 | |

| N2205 | 2505 | 25 | 52 | 18 | 1.1 | 0.6 | 24100 | 23300 | 10600 | 13100 | 0.18700 | |

| NJ2205 | C0G42505 | 25 | 52 | 18 | 1 | 1 | 24100 | 23300 | 10600 | 13100 | 0.17000 | |

| NU2205 | 32505 | 25 | 52 | 18 | 1.1 | 0.6 | 24100 | 23300 | 10600 | 13100 | 0.16530 | |

| NU2205/C3 | 25 | 52 | 18 | 1 | 0.6 | 21400 | 22800 | 10600 | 13100 | 0.16530 | ||

| NU2205EV | 25 | 52 | 18 | 1 | 0.6 | 41400 | 43300 | 9200 | 11400 | 0.16520 | ||

| N305 | 2305 | 25 | 62 | 17 | 1.1 | 1.1 | 29100 | 25200 | 9200 | 11400 | 0.23430 | |

| N305ENTN1/C3 | 25 | 62 | 17 | 1.1 | 0.5 | 41500 | 37400 | 9200 | 11400 | 0.23340 | ||

| NF305 | 12305 | 25 | 62 | 17 | 1.1 | 1.1 | 29100 | 25200 | 9200 | 11400 | 0.24330 | |

| NJ305 | 42305 | 25 | 62 | 17 | 1.1 | 1.1 | 29100 | 25200 | 9200 | 11400 | 0.24580 | |

| NJ305/C3 | C3G42305 | 25 | 62 | 17 | 1.1 | 1.1 | 29100 | 25200 | 9200 | 11400 | 0.24580 | |

| NJ305E | 42305E | 25 | 62 | 17 | 1.1 | 1.1 | 41500 | 37400 | 9200 | 11400 | 0.27100 | |

| NJ305ETN1 | 25 | 62 | 17 | 1.1 | 1.1 | 41500 | 37400 | 8900 | 10500 | 0.24364 | ||

| NU305 | 32305 | 25 | 62 | 17 | 1.1 | 1.1 | 29100 | 25200 | 9200 | 11400 | 0.23970 | |

| NUP305 | 25 | 62 | 17 | 1.1 | 1.1 | 29100 | 25200 | 9200 | 11400 | 0.25551 | ||

| NUP305E | 25 | 62 | 17 | 1.1 | 1.1 | 41500 | 37400 | 8900 | 10500 | 0.28505 | ||

| NUP305N | C0G192305 | 25 | 62 | 17 | 1.1 | 1.1 | 29100 | 25200 | 9200 | 11400 | 0.26300 | |

| NCL305 | 157105 | 25 | 62 | 17 | 1.1 | 1.1 | 39500 | 37800 | 8900 | 10500 | 0.24600 | |

| NU2305E | 25 | 62 | 24 | 1.1 | 1.1 | 57000 | 56100 | 2250 | 4500 | 0.36939 | ||

| NJ2305E | 25 | 62 | 24 | 1.1 | 1.1 | 57000 | 56100 | 7800 | 9200 | 0.37739 | ||

| NJ2305EV/C4 | C4G532605E | 25 | 62 | 24 | 1.1 | 1.1 | 66300 | 69700 | 7800 | 9200 | 0.36920 | |

| NJ2305VH | 25 | 62 | 24 | 1.1 | 1.1 | 63000 | 57000 | 2250 | 4500 | 0.36950 | ||

| NUP2305E | 25 | 62 | 24 | 1.1 | 1.1 | 57000 | 56100 | 7800 | 9200 | 0.37657 | ||

| NCL2305 | 102605 | 25 | 62 | 24 | 1.5 | 1.1 | 57700 | 61400 | 7800 | 9200 | 0.35800 | |

| 30 | NUP44494 | 30 | 61.93 | 23.8 | 1.1 | 1.1 | 63300 | 75500 | 2500 | 5000 | 0.34000 | |

| N206 | 2206 | 30 | 62 | 16 | 1 | 0.6 | 23900 | 22200 | 9400 | 11300 | 0.20380 | |

| N206E | 2206E | 30 | 62 | 16 | 1 | 0.6 | 36800 | 34400 | 8900 | 10500 | 0.24000 | |

| NJ206 | 42206 | 30 | 62 | 16 | 1 | 0.6 | 23900 | 22200 | 9400 | 11300 | 0.23380 | |

| NJ206E | C0G42206E | 30 | 62 | 16 | 1 | 0.6 | 39100 | 37300 | 8900 | 10500 | 0.23080 | |

| NJ206ETN1 | 30 | 62 | 16 | 1 | 0.6 | 39100 | 37300 | 8900 | 10500 | 0.23080 | ||

| NU206 | 32206 | 30 | 62 | 16 | 1 | 0.6 | 23900 | 22200 | 9400 | 11300 | 0.21130 | |

| NU206E | 32206E | 30 | 62 | 16 | 1 | 0.6 | 39100 | 37300 | 8900 | 10500 | 0.22310 | |

| NUP206E | 92206E | 30 | 62 | 16 | 1 | 0.6 | 39100 | 37300 | 8900 | 10500 | 0.23540 | |

| NUP206E/C4 | 30 | 62 | 16 | 1 | 1 | 39100 | 37300 | 8900 | 10500 | 0.23510 | ||

| NCL206 | 157106 | 30 | 62 | 16 | 1 | 0.6 | 33800 | 35100 | 8900 | 10500 | 0.22400 | |

| NJ2206ETN1 | 30 | 62 | 20 | 1.0 | 0.6 | 48900 | 49800 | 8900 | 10500 | 0.25792 | ||

| NJ2206E | 30 | 62 | 20 | 1.0 | 0.6 | 48900 | 49800 | 8900 | 10500 | 0.34970 | ||

| NJ2206E.TVP | 30 | 62 | 20 | 1 | 1 | 48900 | 49800 | 2500 | 5000 | 0.25792 | ||

| N306 | 2306 | 30 | 72 | 19 | 1.1 | 1.1 | 35900 | 31900 | 7800 | 9200 | 0.34480 | |

| NJ306 | 42306 | 30 | 72 | 19 | 1.1 | 1.1 | 35900 | 31900 | 7800 | 9200 | 0.35240 | |

| NJ306E | 30 | 72 | 19 | 1.1 | 1.1 | 53200 | 55710 | 7000 | 8500 | 0.40082 | ||

| NJ306E/C3 | 30 | 72 | 19 | 1.1 | 1.1 | 53200 | 55710 | 7000 | 8500 | 0.40082 | ||

| NU306 | 32306K | 30 | 72 | 19 | 1.1 | 1.1 | 35900 | 31900 | 7800 | 9200 | 0.34590 | |

| NU306E | 30 | 72 | 19 | 1.1 | 1.1 | 53200 | 55710 | 7800 | 9200 | 0.39282 | ||

| NU306MN/P63 | 30 | 72 | 19 | 1.1 | 1.1 | 35100 | 38600 | 7800 | 9200 | 0.38100 | ||

| NUP306 | 92306 | 30 | 72 | 19 | 1.1 | 1.1 | 35900 | 31900 | 7800 | 9200 | 0.36950 | |

| NFP306 | 22306K | 30 | 72 | 19 | 1.1 | 1.1 | 35900 | 31900 | 7800 | 9200 | 0.37000 | |

| RO-694 | 30 | 80 | 23 | 1.1 | 1 | 75400 | 81100 | 7800 | 9200 | 0.60065 | ||

| 32 | NCL6/32V | 32 | 62 | 18 | 1.1 | 0.6 | 53400 | 56200 | 7000 | 8500 | 0.23670 | |

| NCL6/32V/P6 | 32 | 62 | 18 | 1.1 | 0.6 | 53400 | 56200 | 7000 | 8500 | 0.23670 | ||

| NUP45622 | 32 | 75 | 20 | 1.1 | 1.1 | 50000 | 44300 | 0.41125 | ||||

| 35 | F-45226 | 35 | 62 | 19 | 1 | 0.6 | 50000 | 53000 | 2750 | 5500 | 0.21513 | |

| R356219 | 35 | 62 | 19 | 1 | 0.6 | 50000 | 53000 | 2750 | 5500 | 0.21513 | ||

| N207 | 2207 | 35 | 72 | 17 | 1.1 | 0.6 | 31400 | 28900 | 8300 | 9900 | 0.29400 | |

| NF207 | C0G12207 | 35 | 72 | 17 | 1.1 | 0.6 | 31400 | 28900 | 8300 | 9900 | 0.30150 | |

| NJ207 | 42207 | 35 | 72 | 17 | 1.1 | 0.6 | 31400 | 28900 | 8300 | 9900 | 0.29950 | |

| NJ207E | 35 | 72 | 17 | 1.1 | 0.6 | 55710 | 55710 | 7800 | 9200 | 0.32630 | ||

| NU207 | 32207 | 35 | 72 | 17 | 1.1 | 0.6 | 31400 | 28900 | 8300 | 9900 | 0.29130 | |

| NUP207 | 92207 | 35 | 72 | 17 | 1.1 | 0.6 | 31400 | 28900 | 8300 | 9900 | 0.32451 | |

| NU2207E | 35 | 72 | 23 | 1.1 | 0.6 | 61600 | 65200 | 2200 | 4300 | 0.41860 | ||

| NJ2207E | 35 | 72 | 23 | 1.1 | 0.6 | 61600 | 65200 | 6600 | 7900 | 0.42960 | ||

| NUP2207E | 92507E | 35 | 72 | 23 | 1.1 | 0.6 | 61600 | 65200 | 6600 | 7900 | 0.44440 | |

| N307 | 2307K | 35 | 80 | 21 | 1.5 | 1.1 | 46400 | 43000 | 7700 | 9200 | 0.45760 | |

| NF307 | 12307K | 35 | 80 | 21 | 1.5 | 1.1 | 46400 | 43000 | 7700 | 9200 | 0.47360 | |

| NJ307 | 42307 | 35 | 80 | 21 | 1.5 | 1.1 | 46400 | 43000 | 7700 | 9200 | 0.48060 | |

| NJ307/C3 | C3G42307 | 35 | 80 | 21 | 1.5 | 1.1 | 46400 | 43000 | 1700 | 3400 | 0.48365 | |

| NJ307E | C0G42307EK | 35 | 80 | 21 | 1.8 | 1.3 | 66500 | 65300 | 6600 | 7900 | 0.48720 | |

| NJ307EV/C4YA | C4G532307EK | 35 | 80 | 21 | 1.5 | 1.1 | 78400 | 81000 | 6100 | 7400 | 0.50150 | |

| C3G42307EK | 35 | 80 | 21 | 1.8 | 1.3 | 66500 | 65300 | 7700 | 9200 | 0.48720 | ||

| NU307 | 32307 | 35 | 80 | 21 | 1.5 | 1.1 | 46400 | 43000 | 7700 | 9200 | 0.46760 | |

| NU307EV1 | 35 | 80 | 21 | 1.5 | 1.1 | 71000 | 71000 | 6600 | 7900 | 0.51243 | ||

| NUP307E | 92307E | 35 | 80 | 21 | 1.5 | 1.1 | 66500 | 65300 | 6600 | 7900 | 0.52340 | |

| NUP307EN | 35 | 80 | 21 | 1.5 | 1.1 | 66500 | 65300 | 6600 | 7900 | 0.53710 | ||

| NUP307EV | 35 | 80 | 21 | 1.5 | 1.1 | 77500 | 79800 | 6600 | 7900 | 0.51390 | ||

| NUP307EV/C3 | 35 | 80 | 21 | 1.5 | 1.1 | 77500 | 79800 | 6600 | 7900 | 0.51390 | ||

| 510148 | 35 | 80 | 23 | 1.1 | 0.6 | 65750 | 77600 | 6600 | 7900 | 0.57100 | ||

| NJ2307E | 35 | 80 | 31 | 1.5 | 1.1 | 93000 | 100500 | 6600 | 7900 | 0.78400 | ||

| NU2307EV4 | 35 | 80 | 31 | 1.5 | 1.1 | 99000 | 109000 | 6600 | 7900 | 0.76425 | ||

| NUP2207X1V/C9YB | 35 | 90 | 23 | 1.1 | 0.6 | 89600 | 93600 | 0.79900 | ||||

| 40 | N208 | 2208 | 40 | 80 | 18 | 1.1 | 1.1 | 43700 | 42900 | 7300 | 8700 | 0.37080 |

| NF208 | 12208 | 40 | 80 | 18 | 1.1 | 1.1 | 43700 | 42900 | 7300 | 8700 | 0.38380 | |

| NJ208 | 42208 | 40 | 80 | 18 | 1.1 | 1.1 | 43700 | 42900 | 7300 | 8700 | 0.39730 | |

| NU208 | 32208 | 40 | 80 | 18 | 1.1 | 1.1 | 43700 | 42900 | 7300 | 8700 | 0.37580 | |

| NUP208 | 92208 | 40 | 80 | 18 | 1.1 | 0.6 | 43700 | 42900 | 7300 | 8700 | 0.39850 | |

| NUP208/P6 | E92208 | 40 | 80 | 18 | 1.1 | 1.1 | 43700 | 42900 | 7300 | 8700 | 0.39860 | |

| NU2208E | 40 | 80 | 23 | 1.1 | 1.1 | 72300 | 77600 | 2000 | 3800 | 0.51782 | ||

| NJ2208E | 42508E | 40 | 80 | 23 | 1.1 | 1.1 | 72300 | 77600 | 6600 | 7900 | 0.53082 | |

| NJ2208E.TVP3.C3 | 40 | 80 | 23 | 1.1 | 1.1 | 70600 | 75200 | 2000 | 3800 | 0.48967 | ||

| NJ2208EV | 40 | 80 | 23 | 1.1 | 1.1 | 84700 | 95100 | 6100 | 7400 | 0.51160 | ||

| N308 | 2308K | 40 | 90 | 23 | 1.5 | 1.5 | 58600 | 56900 | 6600 | 7900 | 0.63650 | |

| NF308 | 12308K | 40 | 90 | 23 | 1.5 | 1.5 | 58600 | 56900 | 6600 | 7900 | 0.66990 | |

| NF308M/P6 | E12308H | 40 | 90 | 23 | 1.5 | 1.5 | 58600 | 56900 | 6600 | 7900 | 0.71990 | |

| NJ308 | 42308K | 40 | 90 | 23 | 1.5 | 1.5 | 58600 | 56900 | 6600 | 7900 | 0.67930 | |

| NJ308ETN1 | 40 | 90 | 23 | 1.5 | 1.5 | 83200 | 81500 | 1500 | 3000 | 0.66350 | ||

| NJ308/C3 | 40 | 90 | 23 | 1.5 | 1.5 | 58600 | 56900 | 1500 | 3000 | 0.67930 | ||

| NU308 | 32308K | 40 | 90 | 23 | 1.5 | 1.5 | 58600 | 56900 | 6600 | 7900 | 0.66610 | |

| NUP308E | 92308E | 40 | 90 | 23 | 1.5 | 1.5 | 82200 | 80300 | 6100 | 7400 | 0.69600 | |

| NUP308N | 192308 | 40 | 90 | 23 | 1.5 | 1.5 | 58600 | 56900 | 6600 | 7900 | 0.72078 | |

| NUP308EN | 192308E | 40 | 90 | 23 | 1.5 | 1.5 | 82200 | 80300 | 6100 | 7400 | 0.72540 | |

| NUP308ENV | 40 | 90 | 23 | 1.5 | 1.5 | 97200 | 157100 | 5900 | 7000 | 0.75710 | ||

| NJ2308E | 40 | 90 | 33 | 1.5 | 1.5 | 113200 | 121100 | 5900 | 7000 | 1.5710 | ||

| NJ2308E.TVP3 | 40 | 90 | 33 | 1.5 | 1.5 | 121000 | 140700 | 1500 | 3000 | 0.95869 | ||

| NUP2308E | 40 | 90 | 33 | 1.5 | 1.5 | 121000 | 140700 | 1500 | 3000 | 1.06100 | ||

| 45 | N209 | 2209 | 45 | 85 | 19 | 1.1 | 1.1 | 45900 | 46900 | 7100 | 8500 | 0.41880 |

| NF209 | 12209 | 45 | 85 | 19 | 1.1 | 1.1 | 45900 | 46900 | 7100 | 8500 | 0.43670 | |

| NF209/C3 | 45 | 85 | 19 | 1.1 | 1.1 | 45900 | 46900 | 7100 | 8500 | 0.43670 | ||

| NF209E | 45 | 85 | 19 | 1.1 | 1.1 | 63000 | 66400 | 6600 | 7900 | 0.47644 | ||

| NJ209 | 42209 | 45 | 85 | 19 | 1.1 | 1.1 | 45900 | 46900 | 7100 | 8500 | 0.44590 | |

| NJ209E | 45 | 85 | 19 | 1.1 | 1.1 | 63000 | 66400 | 6600 | 7900 | 0.42995 | ||

| NJ209ECP | 45 | 85 | 19 | 1.1 | 1.1 | 63000 | 66400 | 7100 | 8500 | 0.42995 | ||

| NJ209ETN1/C3 | 45 | 85 | 19 | 1.1 | 1.1 | 63000 | 66400 | 7100 | 8500 | |||

| NU209 | 32209 | 45 | 85 | 19 | 1.1 | 1.1 | 45900 | 46900 | 7100 | 8500 | 0.43400 | |

| NUP2209E | 45 | 85 | 23 | 1.1 | 1.1 | 76000 | 84500 | 6600 | 7900 | 0.59384 | ||

| NUP2209EN | 45 | 85 | 23 | 1.1 | 1.1 | 76000 | 84500 | 6600 | 7900 | 0.58764 | ||

| N309 | 2309K | 45 | 100 | 25 | 1.5 | 1.5 | 72900 | 69900 | 5900 | 7000 | 0.82390 | |

| NF309 | 12309 | 45 | 100 | 25 | 1.5 | 1.5 | 72900 | 69900 | 5900 | 7000 | 0.86840 | |

| NF309M/P6 | E12309H | 45 | 100 | 25 | 1.5 | 1.5 | 72900 | 69900 | 5900 | 7000 | 0.70829 | |

| NJ309 | 42309 | 45 | 100 | 25 | 1.5 | 1.5 | 72900 | 69900 | 5900 | 7000 | 0.87490 | |

| NJ309E | 45 | 100 | 25 | 1.5 | 1.5 | 99200 | 157100 | 5000 | 6000 | 0.97560 | ||

| NU309 | 32309K | 45 | 100 | 25 | 1.5 | 1.5 | 72900 | 69900 | 5900 | 7000 | 0.85180 | |

| NU309E | 45 | 100 | 25 | 1.5 | 1.5 | 99200 | 157100 | 5000 | 6000 | 0.97990 | ||

| NUP309 | 92309 | 45 | 100 | 25 | 1.5 | 1.5 | 72900 | 69900 | 5900 | 7000 | 0.89440 | |

| NUP309N | 192309 | 45 | 100 | 25 | 1.5 | 1.5 | 72900 | 69900 | 5900 | 7000 | 0.91000 | |

| NUP309NR | 45 | 100 | 25 | 1.5 | 1.5 | 72900 | 69900 | 5900 | 7000 | 0.91477 | ||

| NUP309EN | 45 | 100 | 25 | 1.5 | 1.5 | 99200 | 157100 | 5000 | 6000 | 0.98110 | ||

| NUP309ENV/C3 | 45 | 100 | 25 | 1.5 | 1.5 | 110500 | 116100 | 4500 | 5300 | 0.97417 | ||

| NUP309ENTN1 | 192309E | 45 | 100 | 25 | 1.5 | 1.5 | 99200 | 157100 | 5000 | 6000 | 0.90400 | |

| NJ2309E | 45 | 100 | 36 | 1.5 | 1.5 | 138800 | 155700 | 5000 | 6000 | 1.38761 | ||

| NU2309E | 45 | 100 | 36 | 1.5 | 1.5 | 138800 | 155700 | 5000 | 6000 | 1.35761 | ||

| 50 | N210 | 2210 | 50 | 90 | 20 | 1.1 | 1.1 | 48100 | 50900 | 6600 | 7900 | 0.47520 |

| NF210 | 50 | 90 | 20 | 1.1 | 1.1 | 48100 | 50900 | 6600 | 7900 | 0.49820 | ||

| NF210C3 | C3G12210 | 50 | 90 | 20 | 1.1 | 1.1 | 48100 | 50900 | 6600 | 7900 | 0.49820 | |

| NF210E | 50 | 90 | 20 | 1.1 | 1.1 | 65900 | 71800 | 6200 | 7300 | 0.53120 | ||

| NJ210 | 42210 | 50 | 90 | 20 | 1.1 | 1.1 | 48100 | 50900 | 6600 | 7900 | 0.48640 | |

| NJ210E | 50 | 90 | 20 | 1.1 | 1.1 | 65900 | 71800 | 6600 | 7900 | 0.53571 | ||

| NJ210ETN/C3 | C3G42210EA | 50 | 90 | 20 | 1.1 | 1.1 | 65900 | 71800 | 6200 | 7300 | 0.48320 | |

| NU210 | 32210 | 50 | 90 | 20 | 1.1 | 1.1 | 48100 | 50900 | 6600 | 7900 | 0.47340 | |

| NU210/P6 | E32210 | 50 | 90 | 20 | 1.1 | 1.1 | 48100 | 50900 | 6600 | 7900 | 0.47340 | |

| NU210ETN/C3 | 50 | 90 | 20 | 1.1 | 1.1 | 65900 | 71800 | 6200 | 7900 | 0.46820 | ||

| NUP210EN | 50 | 90 | 20 | 1.1 | 1.1 | 65900 | 71800 | 6200 | 7900 | 0.52420 | ||

| NUP210E | 50 | 90 | 20 | 1.1 | 1.1 | 65900 | 71800 | 6200 | 7900 | 0.52620 | ||

| NU2210ETN/C3 | C3G32510EA | 50 | 90 | 23 | 1.1 | 1.1 | 79500 | 91500 | 6200 | 7300 | 0.54970 | |

| NJ2210ETN1 | 50 | 90 | 23 | 1.1 | 1.1 | 79500 | 91500 | 1700 | 3300 | 0.56470 | ||

| NJ2210E.TVP3.C3 | 50 | 90 | 23 | 1.1 | 1.1 | 77600 | 88600 | 1700 | 3300 | 0.56800 | ||

| NJ2210E.TVP3 | 50 | 90 | 23 | 1.1 | 1.1 | 77600 | 88600 | 1700 | 3300 | 0.56800 | ||

| NUP2210E | 50 | 90 | 23 | 1.1 | 1.1 | 79500 | 91500 | 6200 | 7300 | 0.63660 | ||

| N310 | 2310 | 50 | 110 | 27 | 2 | 2 | 88900 | 88800 | 5400 | 6300 | 1. 0571 0 | |

| NF310 | 12310 | 50 | 110 | 27 | 2 | 2 | 88900 | 88800 | 5400 | 6300 | 1.10120 | |

| NJ310 | 42310 | 50 | 110 | 27 | 2 | 2 | 88900 | 88800 | 5400 | 6300 | 1.14800 | |

| NJ310E | 50 | 110 | 27 | 2 | 2 | 112100 | 116000 | 5000 | 6000 | 1.27325 | ||

| NJ310N | C0G262310K | 50 | 110 | 27 | 2 | 2 | 88900 | 88800 | 5400 | 6300 | 1.15300 | |

| NU310 | 32310 | 50 | 110 | 27 | 2 | 2 | 88900 | 88800 | 5400 | 6300 | 1.12560 | |

| NUP310 | 92310 | 50 | 110 | 27 | 2 | 2 | 88900 | 88800 | 5400 | 6300 | 1.20000 | |

| NUP310NV | 50 | 110 | 27 | 2 | 2 | 128200 | 144700 | 5400 | 6300 | 1.20800 | ||

| NUP310ENV/C3 | 50 | 110 | 27 | 2 | 2 | 128200 | 144700 | 5000 | 6000 | 1.20800 | ||

| NCL310 | 157110 | 50 | 110 | 27 | 2 | 2 | 111300 | 122300 | 5400 | 6300 | 1.17000 | |

| N410 | 2410 | 50 | 130 | 31 | 2.1 | 2.1 | 132300 | 127600 | 5400 | 6300 | 2.26000 | |

| NJ410 | 42410K | 50 | 130 | 31 | 2.1 | 2.1 | 132300 | 127600 | 5400 | 6300 | 2.26000 | |

| 55 | N211 | 2211 | 55 | 100 | 21 | 1.5 | 1.1 | 57900 | 62200 | 6000 | 7100 | 0.62130 |

| NF211 | 12211 | 55 | 100 | 21 | 1.5 | 1.1 | 57900 | 62200 | 6000 | 7100 | 0.65370 | |

| NF211E | 12211E | 55 | 100 | 21 | 1.5 | 1.1 | 86100 | 98700 | 5400 | 6500 | 0.76600 | |

| NJ211 | 42211 | 55 | 100 | 21 | 1.5 | 1.1 | 57900 | 62200 | 6000 | 7100 | 0.64510 | |

| NJ211/C3 | 55 | 100 | 21 | 1.5 | 1.1 | 55710 | 32000 | 6000 | 7100 | 0.64510 | ||

| NJ211E | 55 | 100 | 21 | 1.5 | 1.1 | 86100 | 98700 | 5400 | 6500 | 0.66160 | ||

| NJ211ECP | 55 | 100 | 21 | 1.5 | 1.1 | 86100 | 98700 | 5400 | 6500 | 0.66160 | ||

| NU211 | 32211 | 55 | 100 | 21 | 1.5 | 1.1 | 57900 | 62200 | 6000 | 7100 | 0.63571 | |

| NU211E | 55 | 100 | 21 | 1.5 | 1.1 | 86100 | 98700 | 5400 | 6500 | 0.71850 | ||

| NUP211 | 55 | 100 | 21 | 1.5 | 1.1 | 57900 | 62200 | 6000 | 7100 | 0.64470 | ||

| NUP211E | 55 | 100 | 21 | 1.5 | 1.1 | 86100 | 98700 | 5400 | 6500 | 0.76060 | ||

| NJ2211E | 55 | 100 | 25 | 1.5 | 1.1 | 101200 | 121500 | 1500 | 3000 | 0.89360 | ||

| NJ2211E/C3 | 3G42511E | 55 | 100 | 25 | 2.0 | 1.1 | 101200 | 121500 | 5400 | 6500 | 0.89360 | |

| NUP2211EN/C3 | 55 | 100 | 25 | 1.5 | 1.1 | 101200 | 121500 | 5400 | 6500 | 0.89240 | ||

| NF311E | 12311E | 55 | 120 | 29 | 2 | 2 | 138100 | 144300 | 4500 | 5300 | 1.60325 | |

| NF311E/C3 | 55 | 120 | 29 | 2 | 2 | 140500 | 147600 | 4500 | 5300 | 1.60145 | ||

| NJ311E | 42311E | 55 | 120 | 29 | 2 | 2 | 138100 | 144300 | 4500 | 5300 | 1.63700 | |

| NUP311EN | 55 | 120 | 29 | 2 | 2 | 140500 | 147600 | 4500 | 5300 | 1.66760 | ||

| NUP311ENV/C3 | 55 | 120 | 29 | 2 | 2 | 153800 | 165700 | 4500 | 5300 | 1.59230 | ||

| 60 | N212 | 2212 | 60 | 110 | 22 | 1.5 | 1.5 | 71800 | 79800 | 5400 | 6500 | 0.82160 |

| NJ212 | 42212 | 60 | 110 | 22 | 1.5 | 1.5 | 71800 | 79800 | 5400 | 6500 | 0.83610 | |

| NJ212E | 60 | 110 | 22 | 1.5 | 1.5 | 96200 | 105600 | 5000 | 6000 | 0.9571 | ||

| NU212 | 32212 | 60 | 110 | 22 | 1.5 | 1.5 | 71800 | 79800 | 5400 | 6500 | 0.82220 | |

| NU212ETN1/C3 | 60 | 110 | 22 | 1.5 | 1.5 | 96200 | 105600 | 5000 | 6000 | 0.79458 | ||

| NUP212E | 60 | 110 | 22 | 1.5 | 1.5 | 96200 | 105600 | 5000 | 6000 | 0.92947 | ||

| NF312 | 12312 | 60 | 130 | 31 | 2.1 | 2.1 | 124800 | 127800 | 4500 | 5400 | 1.86900 | |

| NF312E | 60 | 130 | 31 | 2.1 | 2.1 | 153100 | 162100 | 4100 | 4900 | 2.02670 | ||

| NF312E/C3 | 60 | 130 | 31 | 2.1 | 2.1 | 153500 | 164600 | 4100 | 4900 | 2.02670 | ||

| NU312E | 60 | 130 | 31 | 2.1 | 2.1 | 135900 | 96000 | 4100 | 4900 | 1.99332 | ||

| NJ312E | 42312E | 60 | 130 | 31 | 2.1 | 2.1 | 153100 | 162100 | 4100 | 4900 | 2. 0571 0 | |

| NUP312ENV/C3 | 60 | 130 | 31 | 2.1 | 2.1 | 185400 | 195200 | 4100 | 4900 | 1.89200 | ||

| N2312E | 60 | 130 | 46 | 2.1 | 2.1 | 225500 | 266700 | 4200 | 5000 | 2.99210 | ||

| NJ2312E | 60 | 130 | 46 | 2.1 | 2.1 | 225500 | 266700 | 4200 | 5000 | 2.98220 | ||

| 65 | N213 | 2213 | 65 | 120 | 23 | 1.5 | 1.5 | 78800 | 87000 | 5000 | 6000 | 1.19000 |

| NF213 | 12213 | 65 | 120 | 23 | 1.5 | 1.5 | 78800 | 87000 | 5000 | 6000 | 1.20500 | |

| NJ213 | 42213 | 65 | 120 | 23 | 1.5 | 1.5 | 78800 | 87000 | 5000 | 6000 | 1.22000 | |

| NJ213E | 65 | 120 | 23 | 1.5 | 1.5 | 15710 | 122300 | 4500 | 5400 | 1.14046 | ||

| NU213 | 32213 | 65 | 120 | 23 | 1.5 | 1.5 | 78800 | 87000 | 5000 | 6000 | 1.20400 | |

| NUP213E | 65 | 120 | 23 | 1.5 | 1.5 | 15710 | 122300 | 5000 | 6000 | 1.16646 | ||

| NUP213EN/C4 | C4G192213E | 65 | 120 | 23 | 1.5 | 1.5 | 15710 | 122300 | 4500 | 5400 | 1.16646 | |

| NU313E | 65 | 140 | 33 | 2.1 | 2.1 | 182800 | 194800 | 4000 | 4700 | 2.37380 | ||

| NJ313E | 65 | 140 | 33 | 2.1 | 2.1 | 182800 | 195300 | 4000 | 4700 | 2.23005 | ||

| NJ313E/C2 | 65 | 140 | 33 | 2 | 2 | 182800 | 194800 | 4000 | 4700 | 2.42280 | ||

| NUP313ENV | 65 | 140 | 33 | 2.1 | 2.1 | 212900 | 244900 | 4000 | 4700 | 2.20000 | ||

| 70 | N214 | 2214 | 70 | 125 | 24 | 1.5 | 1.5 | 82100 | 93500 | 4800 | 5700 | 1.13770 |

| NF214 | 12214 | 70 | 125 | 24 | 1.5 | 1.5 | 82100 | 93500 | 4800 | 5700 | 1.17340 | |

| NF214E/C3 | 70 | 125 | 24 | 1.5 | 1.5 | 123600 | 144500 | 4800 | 5700 | 1.27412 | ||

| NF214E/YB2 | 70 | 125 | 24 | 4.3 | 1.5 | 121000 | 140700 | 4500 | 5400 | 1.27412 | ||

| NJ214 | 42214 | 70 | 125 | 24 | 1.5 | 1.5 | 82100 | 93500 | 4800 | 5700 | 1.20300 | |

| NJ214E | 70 | 125 | 24 | 1.5 | 1.5 | 121000 | 140700 | 4500 | 5400 | 1.27262 | ||

| NU214 | 32214 | 70 | 125 | 24 | 1.5 | 1.5 | 82100 | 93500 | 4800 | 5700 | 0.84500 | |

| NUP214E | 92214E | 70 | 125 | 24 | 1.5 | 1.5 | 121000 | 140700 | 4500 | 5400 | 1.30600 | |

| NF314E | 70 | 150 | 35 | 2.1 | 2.1 | 25710 | 226000 | 3700 | 4400 | 2.98900 | ||

| NU314E | 70 | 150 | 35 | 2.1 | 2.1 | 25710 | 226000 | 3700 | 4400 | 2.94617 | ||

| NJ314E | 70 | 150 | 35 | 2.1 | 2.1 | 25710 | 226000 | 3700 | 4400 | 3.05717 | ||

| NJ314E/C9 | 70 | 150 | 35 | 2.1 | 2.1 | 25710 | 226000 | 3700 | 4400 | 3.05717 | ||

| NUP314ENV/C4 | 70 | 150 | 35 | 2.1 | 2.1 | 236300 | 253300 | 3700 | 4400 | 3.57102 | ||

| NJ2314VH | 70 | 150 | 51 | 2.1 | 2.1 | 335000 | 455000 | 3700 | 4400 | 4.34670 | ||

| 75 | N215 | 2215 | 75 | 130 | 25 | 1.5 | 1.5 | 95100 | 15710 | 4500 | 5400 | 1.20430 |

| NF215 | 12215 | 75 | 130 | 25 | 1.5 | 1.5 | 95100 | 15710 | 4500 | 5400 | 1.24030 | |

| NJ215 | 42215 | 75 | 130 | 25 | 1.5 | 1.5 | 95100 | 15710 | 4500 | 5400 | 1.24890 | |

| NU215 | 32215 | 75 | 130 | 25 | 1.5 | 1.5 | 95100 | 15710 | 4500 | 5400 | 1.21780 | |

| NU215E | 75 | 130 | 25 | 1.5 | 1.5 | 132200 | 160500 | 4200 | 5000 | 1.32420 | ||

| 80 | N216 | 2216 | 80 | 140 | 26 | 2 | 2 | 118600 | 141600 | 4200 | 5000 | 1.72000 |

| NJ216 | 42216 | 80 | 140 | 26 | 2 | 2 | 108500 | 125900 | 4200 | 5000 | 1.79000 | |

| NU216 | 32216 | 80 | 140 | 26 | 2 | 2 | 118600 | 141600 | 4200 | 5000 | 1.75000 | |

| 85 | NJ217 | 42217 | 85 | 150 | 28 | 2 | 2 | 122800 | 144000 | 4000 | 4700 | 2.17000 |

Company Profile

HangZhou JPG bearing & Equipment co ltd

Excellent Manufacturer of Bearings

*The domentic Leading numerical control production equipment ensures the accuracy consisitency and stability of the products .

*Advanced production equipment and high quality tecnician team ensure the quality of bearing products .

*Advanced automation equipment ensure the quality of products while taking into account the production efficiency .

Leading Equipment

JPG Bearingis a comprehensive manufacture and service providers with world’s leading bearing manufacture process and management technique in china. We are selling all kinds of ball and roller bearings products with international standard and technology level of low noise, high load and long life. Welcome to inquiry!

Main products

1.Taper roller bearing

2.Deep groove ball bearing

3.cylindrical roller bearing

3.spherical roller bearing

4.linear bearing

5.pillow block bearing

6 OEM all knid of famous brand

7. Non-standard bearing

Quality Testing

Rigorous Testing

Perfect precision testing equipment ,fullly meet the requirements of bearing R&D and manufacturing .Strict and rigourour quality inspectors strictly abide by product quality standards and strictly control the whole process of products from test to prodution.

High -ending tessing equipment ,professional operation technicians and rigorous procrssing procedures an the guarantee of quality

with the unremitting purcuit of perfec products ,the company has established the industry’s top testing laboratory ,sound quality control rules,and a well -trained professional testing team.Every process from raw materials of finished products is sticklty tested to ensure high quality products. Delivere to the customer .

Packaging & Shipping

Packaging:

1. Neutral Package: Plastic Bag + Carton + Pallet;

2. Commercial Package: Plastic Bag + Box + Carton + Pallet;

3. As the clients’ requirement.

Delivery:

1. Less than 1000 pcs , we will send by express. ( Door to Door, Convenient ),

or by air transport. ( Fastest and safest, but expensive )

2. More than 1000pcs , we will send by sea. ( Cheapest, safe )

FAQ

FAQ

1. Can I get some samples?

A: Yes, sample is available for quality check and market test.

2. Can we do our logo or brand on the package?

A: Yes, we can do OEM.

3. What’s the delivery time?

A: It usually takes about 10-25 working days for production based on specifications for your order and quantity.

4. What’s your payment terms?

A: We usually accept T/T or L/C at sight as the main payment

terms, an d other payment can also be negotiated.

5. What’s your warranty terms?A: We offer different warranty time for different components,

please contact us for details

Payment:

1. Less than 1000 pcs , 100% T/T, Western Union in advance.

2. Between 1000-10000pcs, TT, Western Union, MoneyGram.

3. More than 10000pcs , TT, L/C ,Western Union, MoneyGram.

Dealing Process:

Send us inqry———Quotation———–Confirmation for all information———-Proforma Invoice————-Payment———–Shipping goods and documents.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Double |

| Outer Dimension: | Large (200-430mm) |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do Tapered Roller Bearings Enhance the Performance of Gearboxes and Transmissions?

Tapered roller bearings play a crucial role in enhancing the performance, efficiency, and reliability of gearboxes and transmissions in various applications, including automotive, industrial machinery, and power generation. These bearings are specifically designed to handle radial and axial loads, making them ideal for supporting rotating shafts and gear assemblies. Here’s how tapered roller bearings contribute to the performance of gearboxes and transmissions:

- Load Distribution:

Gearboxes and transmissions experience a combination of radial and axial loads due to gear meshing and torque transmission. Tapered roller bearings distribute these loads evenly across the rolling elements, minimizing stress concentrations and ensuring reliable operation.

- Axial Load Handling:

As gears transmit torque, axial forces are generated. Tapered roller bearings are capable of handling both radial and axial loads, ensuring stable and controlled motion while accommodating the forces generated by gear engagement.

- Reduced Friction and Wear:

Tapered roller bearings are designed with precision-matched rollers and raceways, reducing friction and wear. This results in smoother gear rotation, reduced heat generation, and extended component life.

- Optimized Axial Preload:

In certain applications, axial preload can be applied to eliminate internal clearance and enhance gear meshing performance. Tapered roller bearings allow for controlled axial preload adjustment, ensuring proper gear engagement and reducing backlash.

- Accurate Gear Alignment:

Tapered roller bearings aid in maintaining accurate gear alignment and positioning. This is critical for achieving smooth gear transitions, preventing misalignment-related wear, and reducing noise and vibration.

- Efficient Power Transmission:

Efficient gear operation is crucial for transmitting power from the input to the output shaft. Tapered roller bearings minimize energy losses due to friction, allowing more power to be efficiently transmitted through the gearbox or transmission.

- High-Speed Capability:

Tapered roller bearings are suitable for high-speed applications, making them suitable for gearboxes and transmissions where rapid gear shifts or changes in rotational speed are required.

- Reduced Noise and Vibration:

The smooth operation of tapered roller bearings contributes to reduced noise and vibration in gearboxes and transmissions. This leads to a quieter and more comfortable user experience.

- Long Service Life:

The robust design and high-quality materials used in tapered roller bearings enhance their durability and resistance to wear. This extends the service life of gearboxes and transmissions, reducing maintenance and replacement frequency.

- Enhanced Gearbox Performance:

Tapered roller bearings optimize the performance of gearboxes and transmissions, contributing to smoother gear shifting, improved fuel efficiency, better power transmission, and overall enhanced drivetrain performance.

Overall, tapered roller bearings are essential components that enhance the efficiency, reliability, and performance of gearboxes and transmissions in a wide range of applications.

What is the impact of proper lubrication on the performance and lifespan of cylindrical roller bearings?

Proper lubrication plays a crucial role in the performance and lifespan of cylindrical roller bearings. Lubrication is essential for reducing friction, minimizing wear, dissipating heat, and preventing corrosion. Let’s explore the impact of proper lubrication in more detail:

- Friction Reduction:

Proper lubrication forms a thin film of lubricant between the rolling elements and raceways of cylindrical roller bearings. This lubricant film separates the surfaces and reduces direct metal-to-metal contact. As a result, friction and sliding resistance are significantly reduced. The reduction in friction helps to minimize energy loss, improve efficiency, and reduce wear on the bearing components.

- Wear Prevention:

Lubrication creates a protective barrier between the rolling elements and raceways, preventing excessive wear. The lubricant film prevents metal-to-metal contact and acts as a cushion, absorbing shock and distributing the load evenly. By reducing wear, proper lubrication helps to prolong the lifespan of cylindrical roller bearings, ensuring reliable performance over an extended period.

- Heat Dissipation:

During operation, cylindrical roller bearings generate heat due to friction. Proper lubrication helps dissipate this heat by carrying it away from the bearing surfaces. The lubricant absorbs and transfers the heat, preventing excessive temperature buildup that could lead to premature failure. Effective heat dissipation through proper lubrication helps maintain the bearing’s operational stability and prevents thermal damage.

- Prevention of Corrosion:

Lubrication acts as a protective layer, preventing the direct contact of moisture or contaminants with the bearing surfaces. This barrier helps to inhibit corrosion and the formation of rust on the bearing components. By keeping the surfaces clean and protected, proper lubrication aids in maintaining the integrity and longevity of cylindrical roller bearings, especially in challenging environments.

- Noise Reduction:

Proper lubrication contributes to reducing noise and vibration in cylindrical roller bearings. The lubricant film acts as a cushion, damping the vibrations and reducing the generation of noise during operation. This is particularly important in applications where noise reduction is critical, such as precision machinery or equipment operating in quiet environments.

- Contamination Control:

Proper lubrication helps in controlling and minimizing the ingress of contaminants into cylindrical roller bearings. The lubricant forms a barrier that helps prevent the entry of dirt, dust, and other particles that could lead to premature wear or damage. By maintaining cleanliness, proper lubrication enhances the overall performance and reliability of the bearing.

In summary, proper lubrication is essential for optimizing the performance and extending the lifespan of cylindrical roller bearings. It reduces friction, minimizes wear, dissipates heat, prevents corrosion, reduces noise, and controls contamination. Bearing manufacturers and operators must follow recommended lubrication practices, including selecting the appropriate lubricant type and viscosity, ensuring proper lubricant replenishment, and adhering to scheduled maintenance intervals, to maximize the benefits of lubrication and ensure the long-term reliability of cylindrical roller bearings.

Can you explain the design and structure of cylindrical roller bearings?

Cylindrical roller bearings have a specific design and structure that enables them to handle high radial loads and moderate thrust loads. Let’s explore the key components and features of cylindrical roller bearings:

- Inner and Outer Rings:

The inner and outer rings of cylindrical roller bearings are typically made of high-quality bearing steel. The inner ring is mounted on the rotating shaft, while the outer ring is usually mounted in a stationary housing. The rings are precision-machined with raceways that serve as the contact surfaces for the cylindrical rollers.

- Cylindrical Rollers:

Cylindrical rollers are the main load-carrying components of the bearing. They are cylindrical in shape and have a high length-to-diameter ratio. The rollers are precision-ground to ensure close tolerances and uniform size distribution. The large contact area between the rollers and the raceways allows for efficient load distribution and reduced stresses.

- Cage:

A cage, also known as a separator, is used to keep the cylindrical rollers evenly spaced and prevent them from coming into contact with each other. The cage is typically made of steel or other materials such as brass or polyamide (nylon). It provides guidance and retains the rollers in position during operation, ensuring smooth rolling motion and preventing roller skewing or jamming.

- Flanges:

Cylindrical roller bearings may have flanges on the inner or outer rings or both. Flanges are raised edges or shoulders that provide axial guidance and help in locating the bearing in the axial direction. The presence of flanges can also improve the overall rigidity and axial load-carrying capacity of the bearing.

- Internal Clearance:

The internal clearance of cylindrical roller bearings refers to the space between the rollers and raceways when there is no external load applied. It affects the bearing’s thermal expansion, running accuracy, and ability to accommodate misalignment or axial displacement. Different levels of internal clearance are available to suit specific application requirements.

- Lubrication:

Cylindrical roller bearings require proper lubrication to minimize friction, reduce wear, and dissipate heat generated during operation. Lubrication helps to maintain the separation between the rolling elements and raceways, preventing metal-to-metal contact and minimizing the risk of premature failure. Common lubrication methods include grease lubrication and oil lubrication.

- Sealing and Protection:

Cylindrical roller bearings can be equipped with various types of seals or shields to prevent the ingress of contaminants and retain lubrication. These seals and shields help to extend the bearing’s service life and maintain its performance by providing protection against moisture, dust, and other external factors that could cause damage or deterioration.

Overall, the design and structure of cylindrical roller bearings allow them to efficiently handle radial loads and moderate thrust loads. The combination of inner and outer rings, cylindrical rollers, cage, flanges, internal clearance, lubrication, and sealing work together to provide reliable and smooth rotational motion in machinery applications.

editor by CX 2024-04-30